Common Rail Direct Injection (CRDi):

Most modern engine fuel systems use an advanced technology known as CRDi or Common Rail Direct Injection. Besides, both petrol and diesel engines use a common ‘fuel rail,’ which supplies the fuel to injectors.

Furthermore, manufacturers refer to this technology as CRDi in diesel engines. However, Petrol engines term it Gasoline Direct Injection (GDI) or Fuel Stratified Injection (FSI). These technologies have a similar design since they consist of a ‘fuel rail’ that supplies fuel to injectors. However, they considerably differ on parameters such as system pressure & type of fuel used.

Working:

Moreover, in Common Rail Direct Injection, the combustion occurs directly in the main combustion chamber. The piston crown locates the chamber in a cavity above its head. Today, manufacturers use CRDi technology to overcome some of the deficiencies of conventional diesel engines. Moreover, they were sluggish, noisy, and poor in performance when implemented. This was true, especially in passenger vehicles.

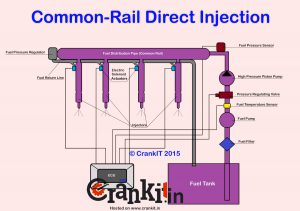

Following Is The Schematic CRDi Line Diagram:

Furthermore, the CRDi technology works, in tandem, with the engine ECU. The ECU gets inputs from various sensors. It then calculates the precise quantity of fuel and timing of injection. As a result, this fuel system features more “intelligent” components in nature. Besides, it controls them electrically/electronically. In addition, the more advanced and electrically operated solenoid injectors replace conventional injectors. And an ECU signal opens them. It depends on engine speed, load, engine temperature, etc.

Furthermore, a Common Rail system uses a fuel rail. Or in simple words, it is a ‘fuel distribution pipe’ that is common for all cylinders. And it maintains optimum residual fuel pressure. Besides, it also acts as a shared fuel reservoir for all the injectors.

Moreover, the fuel rail constantly stores and supplies the fuel to the solenoid valve injectors at the required pressure in the CRDi system. Thus, it is quite the opposite of the fuel injection pump supplying diesel thru’ independent fuel lines to injectors. So it was in the case of earlier generation direct injection (DI) design.

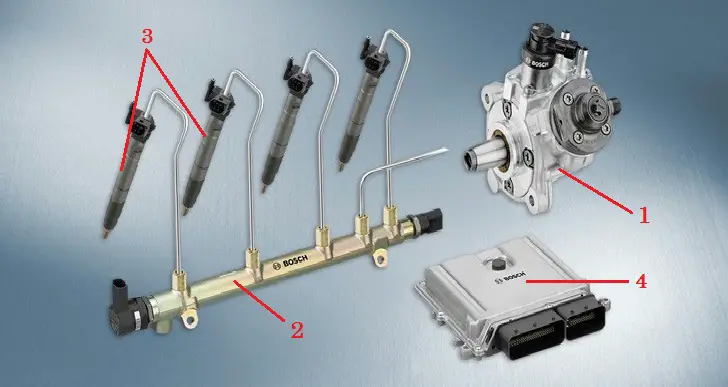

Components of Common Rail Direct Injection System –

1. High-Pressure Fuel Pump

2. Common Fuel Rail

3. Injectors

Working Principle:

Furthermore, a high-pressure pump supplies pressurized fuel. First, the pump compresses the fuel at about 1,000 bar or 15,000 psi pressures. Then, it delivers the pressurized fuel via a high-pressure pipe to the inlet of the fuel rail. Next, the fuel rail distributes the fuel to individual injectors. Thus, it injects the fuel into the combustion chamber.

Moreover, most modern CRDi engines use the Unit-Injector system with a Turbocharger. Thus, it increases power output and meets stringent emission norms. Additionally, it improves engine power, throttle response, and fuel efficiency. Besides, it also controls emissions. Barring some design changes, the basic principle & working of the CRDi technology remains primarily the same across the board. However, its performance depends mainly on the combustion chamber design, fuel pressures, and the type of injectors used.

Moreover, the manufacturers use custom acronyms to make their diesel CRDi products stand out from the competition. E.g., Mercedes-Benz uses the ‘CDI’ acronym for their CRDi engines, while BMW & Volvo uses just the letter ‘D.’ Tata Motors uses two acronyms to describe this technology. They use ‘CR4’ and ‘DiCOR’ for this system. Furthermore, Renault & Nissan uses the term ‘DCi,’ while FIAT uses ‘JTD.’

Honda uses the terms ‘i-CTDi,’ and ‘i-DTEC.’ Chevrolet uses the term ‘VCDi,’ while Ford uses ‘TDCi.’ On the other hand, Volkswagen uses the term ‘TDI.’ The complete list of all the acronyms is as follows.

Various CRDi Acronyms That Are In Use:

| SL. | Acronym | Company |

| 1 | CDI | Mercedes Benz |

| 2 | CRDi | Hyundai |

| 3 | CR4 | Tata |

| 4 | CRDe | Mahindra |

| 5 | D | BMW, Volvo |

| 6 | DiCOR | Tata |

| 7 | DDiS | Suzuki |

| 8 | D-4D | Toyota |

| 9 | DCi | Renault, Nissan |

| 10 | DI-D | Mitsubishi |

| 11 | i-CTDi, i-DTEC | Honda |

| 12 | JTD | Fiat |

| 13 | VCDi | Chevrolet |

| 14 | TDCi | Ford |

| 15 | TDITM | Volkswagen |

|

CRDi Acronyms |

• TDI™ – Turbocharged Direct Injection – Volkswagen group developed, produced & trademarked this term. It comprises a turbo-diesel engine combined with Cylinder-Direct Injection.

Watch CRDi Engine Animation Here:

Keep reading: Electronic fuel injection technology >>