The Purpose of a Fuel Injector:

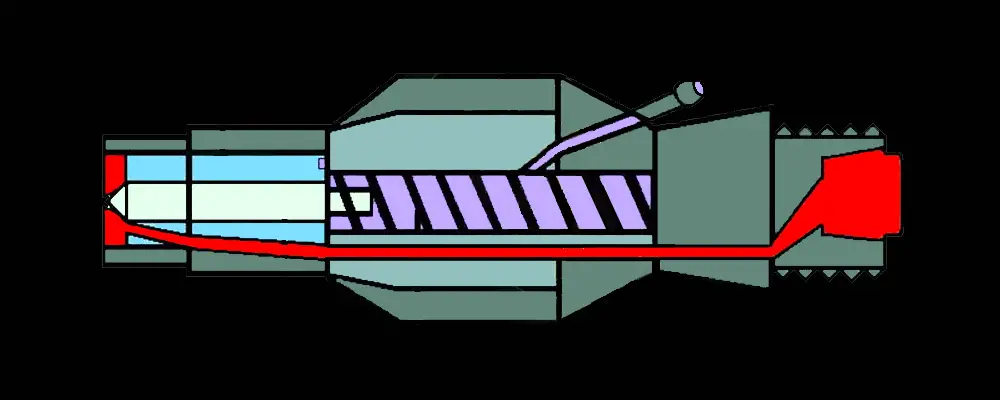

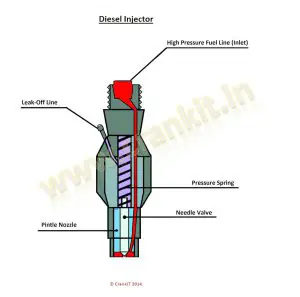

The purpose of a fuel injector is to spray the fuel in atomized or mist form so that it burns entirely & uniformly. Fuel Injection Pump (FIP) supplies pressurized diesel fuel thru’ high-pressure lines to each injector’s inlet port. However, the conventional or first-generation injectors open with hydro-mechanical pressure. Inside the conventional injector, a spring holds the needle valve in a ‘closed’ position until the pressure in the high-pressure lines reaches the specific value. As seen in the diagram below, earlier generation DI & IDI diesel engines used conventional injectors.

Working principle of a conventional fuel injector:

The needle valve is controlled precisely by a pressure-sensitive spring. It lifts off its seat while spraying the diesel into the cylinder in highly atomized or mist form. The moment the pressure drops, the needle valve comes back to its seat, which causes the injection to stop. The injection nozzle has extremely critical tolerances. The clearance between its moving parts is barely 0.002 mm or 2 microns.

Modern-day injector unit forces the diesel through a small opening in the nozzle of merely 0.25 mm² size. As a result, the injected fuel quantity can vary from 1 mm³ to 350 mm³. Conventional injectors open and close hydro-mechanically. They have average nozzle opening pressures ranging from 140 to 210 kg/cm2. Besides, a modern-day Bosch unit sprays the diesel at a speed of 2,000 km/h. Bosch and Lucas are the world’s leading manufacturers of diesel nozzles.

Working principle a Petrol Injector:

Newer generation petrol injectors are pretty different in construction and size than conventional diesel injectors. The Gasoline Direct Injection (GDI) engine generates the air-fuel mixture inside the combustion chamber. The inlet valve opening allows only the fresh air to come in. While high-pressure injectors inject the petrol into the combustion chamber, it improves combustion chamber cooling. Thus, it enables higher engine efficiency due to higher compression, which, in turn, increases fuel efficiency and torque.

A high-pressure pump feeds the fuel to a high-pressure fuel rail (aka common rail). Besides, the Bosch HDEV5 High-pressure solenoid-injector has a nominal system pressure of up to 20 MPa and a Droplet size/SMD (Sauter Mean Diameter) only 15 μm. The injectors fit onto the fuel-rail/common rail. Moreover, the injectors meter and atomize the fuel extremely rapidly at high pressure. Additionally, the injectors provide an optimum mixture and spray petrol into the combustion chamber.

For more information, read about GDI.

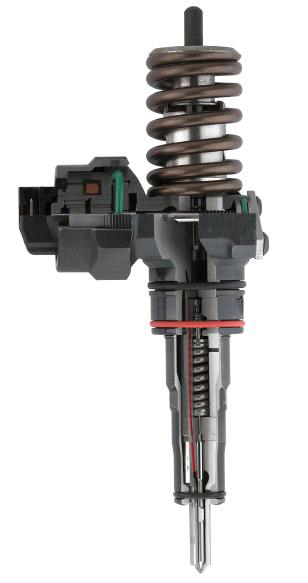

What’s a Unit Injector?

Furthermore, fuel injection systems on the CRDi diesel engines use ‘Unit-Injector’ or the ‘Pump/Injector.’ It merges the functions of an injector-nozzle and the injection pump into a single unit. This design consists of an individual pump assigned to each cylinder rather than a common pump used for all cylinders in earlier generation models.

In this system, the pump and nozzle merge into a single compact assembly that directly fits on the cylinder head. This design eliminates the need for high-pressure fuel pipes. Instead, the integral ducts machined directly into the cylinder head supply the diesel. Thus, it helps to eliminate the potential failures of fuel pipe leakages.

Functioning of Unit Injector:

While functioning, an overhead camshaft operates a low-pressure fuel delivery pump. Subsequently, it supplies diesel to the fuel ducts in the cylinder head and into the inlet port of all injectors. To drive the plunger pump inside the injector, it uses a shared camshaft. This design can deliver higher injection pressure of up to 2,200 bar and accurate injection timing. Also, it precisely controls the amount of fuel injected. Additionally, a solenoid valve operates as the on-off switch to supply the fuel to the injector.

Piezoelectric Injector:

The most advanced type of injector is, undoubtedly, the ‘Piezoelectric-Injector.’ It provides increased precision for the latest generation of CRDi engines and creates fuel pressures up to 3,000 bar or 44,000 psi. Besides, these modern-day fuel-injectors work on the ‘Piezo’ principle. The word ‘Piezo’ comes from the Greek word ‘piezein,’ which means squeezing or pressing.

A Piezo actuator consists of hundreds of ceramic wafers stacked one above the other in the injector. Piezo crystals can change their structure in just a few thousandths of a second when electrically charged by expanding slightly. This expansion of the stack results in its linear movement. It is then transmitted directly to the injector needle without any mechanical linkage between them. As a result, the injectors open/close within a few milliseconds (a thousandth of a second). Consequently, it can inject a tiny amount of fuel, weighing less than one-thousandth of a gram, and distribute it finely.

The Piezoelectric-Injectors have:

1. Very high speed of operation

2. Extremely rapid response time

3. Repeatability of the movement of the valve

4. Precise apportioning of the injected fuel

5. Greater frequency – up to seven injections per combustion cycle

The Piezo-Injectors:

1. Optimize combustion of the air-fuel mixture.

2. Lower fuel consumption.

3. Reduce pollutants lower emissions.