What is Direct Injection Technology?

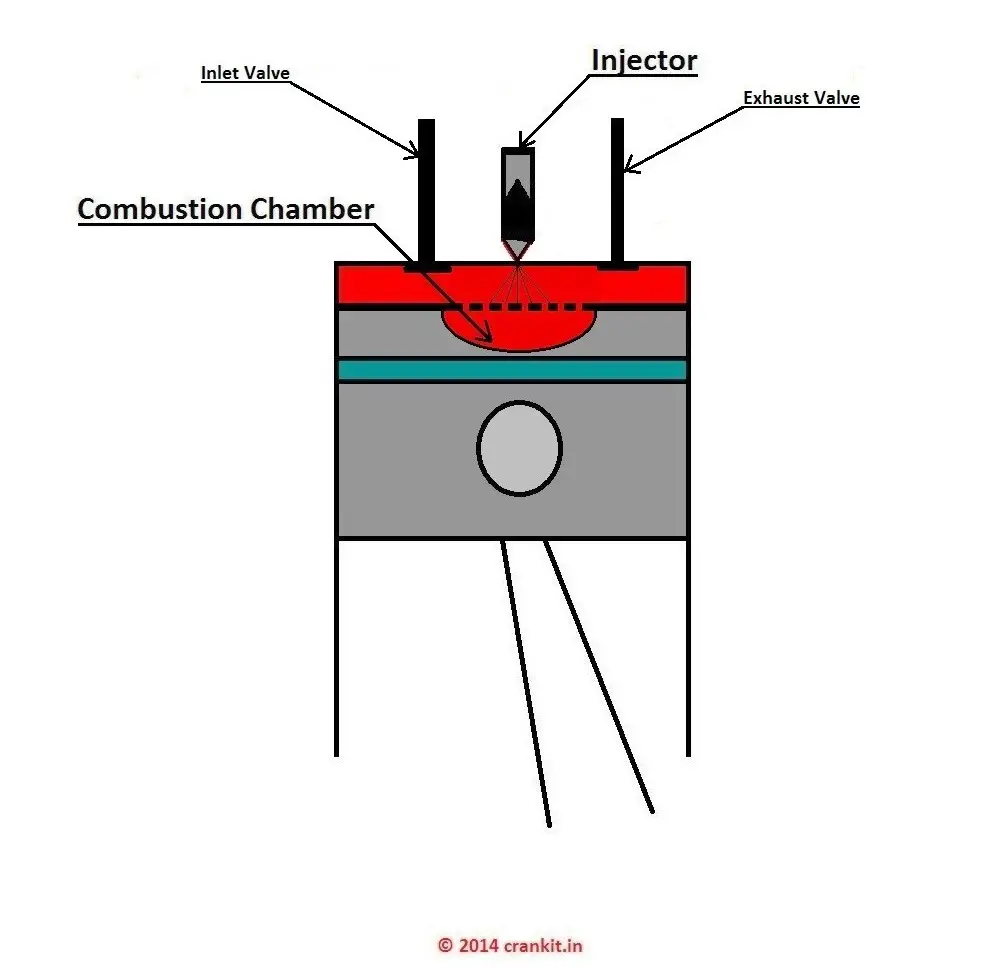

Firstly, Diesel Direct Injection (DI) is a basic type of fuel injection system which many earlier generation diesel engines used. The simple DI diesel engines inject the fuel into the combustion chamber above the piston directly. The compression of air inside the combustion chamber raises its temperature above 400oC. Then, it ignites the diesel-fuel injected into the combustion chamber. Hence, the diesel engines are also known as ‘Compression Ignition’ engines.

This technology i.e. simple DI engine differs in the method by which it supplies the diesel to the injectors and operates them to its successor Common-Rail Direct injection (CRDi). Moreover, it was in vogue until the development of the latter. At present, some heavy diesel vehicles such as utility vehicles, trucks, buses & generators still use DI technology.

The fuel system of DI Technology consists of following parts:

- Fuel Injection Pump (FIP)

- Injectors

- High-Pressure Lines

- Fuel feed pump

- Fuel Filter

- Governor

Fuel Injection Pump in Direct Injection Engines:

The sole function of the Fuel Injection Pump is to supply the accurately measured amount of fuel to each cylinder at specific time intervals in accordance with the position of the piston.

The fuel injection pump compresses the fuel to high pressure and meters the fuel quantity to be injected according to the engine load & speed. Then, it supplies the pressurized diesel to injectors through separate fuel lines.

Technically, there are two different types of FIPs which the DI engines widely use. One is an in-line pump (plunger type) while the other is a rotary pump (distributor type) with a mechanical/pneumatic governor. Furthermore, the governor regulates the engine idling and also maximum speed by controlling the amount of fuel delivery.

Fuel Injection Pump’s parts are machined with narrower tolerances in order to achieve a high degree of precision. The engine oil poured into it from the oil port provides lubrication to the parts of an in-line injection pump whereas the rotary fuel pump is self-lubricating type by diesel.

Advantages of conventional DI Technology:

- Higher low-end torque

- Sturdiness

- Lower maintenance

- Longer engine life

Disadvantages of conventional DI Technology:

- Higher NVH (Noise, Vibrations & Harshness) levels

- Sluggish in operation

- Lower engine speeds & BHP

- Heavier engine components

Earlier generation multi-utility vehicles in India such as Mahindra Armada, Toyota Qualis, Tata Spacio, etc. used this type of engine. Later, newer generation vehicles switched to Common-Rail-Direct-Injection (CRDi) due to stricter emission control.

Watch How Direct Injection Diesel engine works here:

Read More: What is Common Rail Direct Injection?>>