Cylinder Head: Construction, Types, and Classification

Automotive manufacturers design the engine to perform according to its application. Similarly, the cylinder heads are also designed to achieve certain performance parameters. The cylinder head is one of the most important and complex designs in the engine. It requires lots of mathematical calculations and precision machining to achieve the desired results from an engine. So, manufacturers use precision machines and methods to design and manufacture cylinder heads.

Materials:

Universally, the head is always cast together with the cylinder block even for single-cylinder engines. Heads cast integral with cylinder blocks have been produced a very few times. This is mainly for the racing engines which avoids the need for a gas-tight joint. However, the head gasket provides a reasonably good tight joint for the purpose. Hence, the manufacturers discontinued this practice.

Earlier, manufacturers used cast iron for the purpose. Nowadays, in order to reduce weight and improve performance, aluminum alloy is the preferred choice. Besides, aluminum alloy cylinder head maintains temperature more uniformly because of better thermal conductivity. Often, manufacturers use aluminum alloy head with cast-iron cylinder block and crankcase.

Grey cast-iron for cylinder head is the same that the cylinder block uses. However, aluminum alloys are usually quite different. They contain 3% copper, 5% silicon and 0.5% manganese in aluminum-alloy. Copper increases the hardness and strength if aluminum over time due to its age-hardening quality. However, it decreases the corrosion resistance as well. There is an alternate alloy which consists of 4.5% silicon, 0.5% manganese and 0.5% magnesium in aluminum-alloy. heavy applications such as commercial engines, rail- engines and marine engines still use cast iron.

Construction:

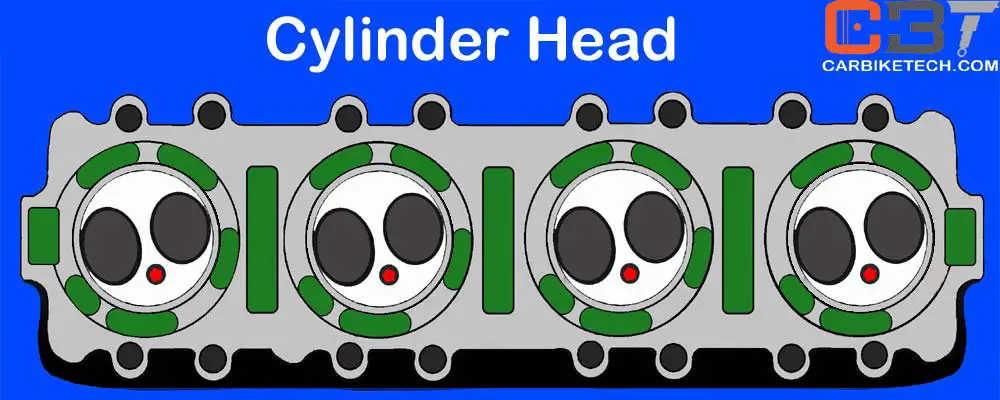

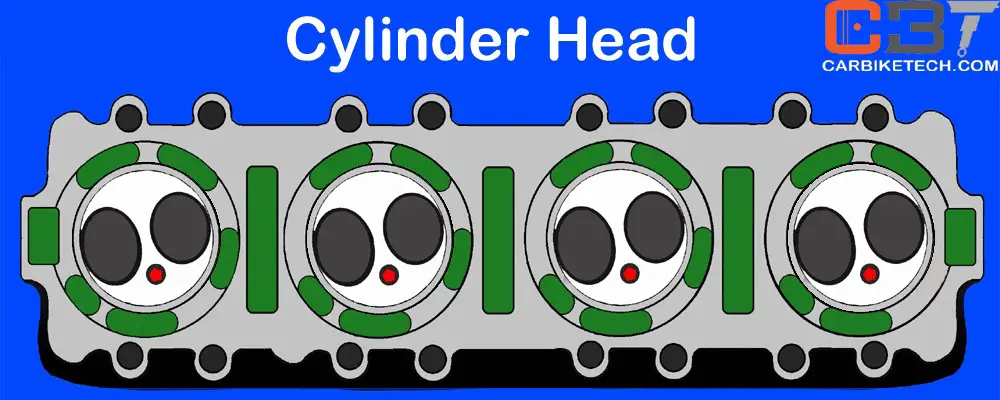

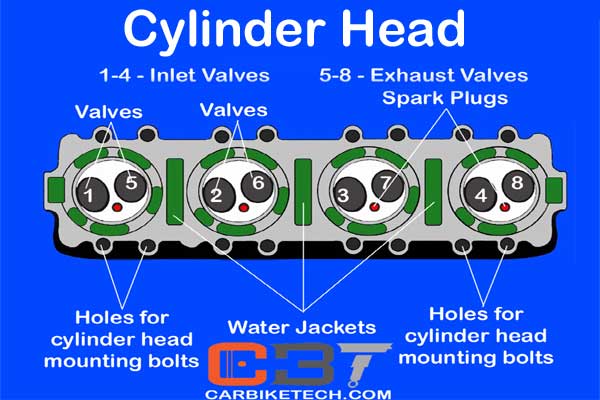

Furthermore, the cylinder head sits on the top surface of the cylinder block. It is fixed with studs/bolts fixed to the block. A head gasket sits between the head and the block. It provides a tight, leak-proof joint. The head has a combustion chamber above each cylinder in which the combustion takes place. It also contains critical engine parts such as the valves, valve guides, spark plugs (petrol engines) or injectors (diesel engines). Besides, the head also has ports, oil passages and water jackets carved inside it to provide lubrication and cooling. However, the overhead camshaft (OHC) engines also have provisions to mount the camshaft and other parts.

Types:

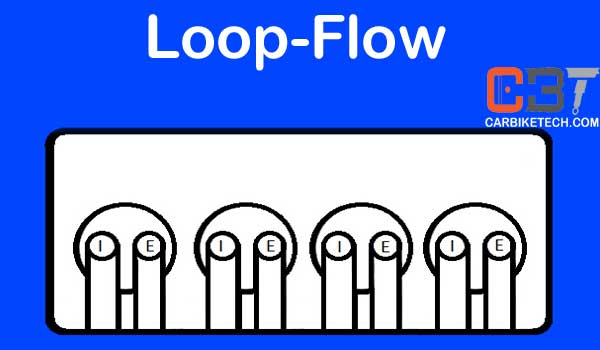

The cylinder head may be classified depending upon the layout of valves and ports. There are mainly three types – Loop-flow type, offset cross-flow type or in-line cross-flow type. In the loop-flow design, the inlet & exhaust manifolds are on the same side which helps pre-heating of the intake air.

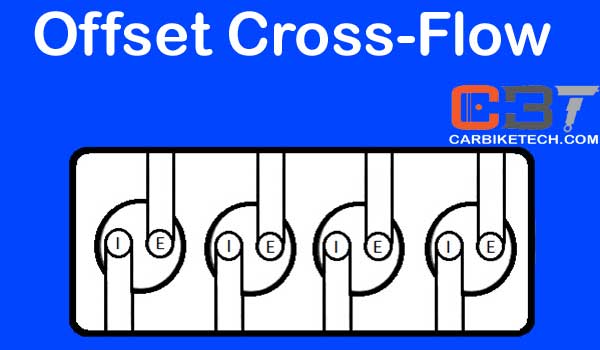

However, when the inlet and exhaust manifolds are on different sides of the cylinder head, it is an offset cross-flow type.

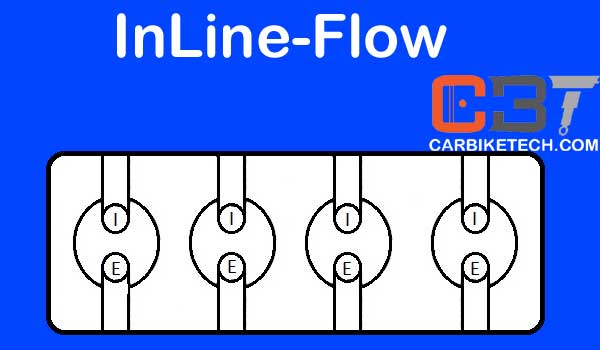

Additionally, this arrangement provides lower exhaust valve temperatures. The inline cross-flow type positions the valves transversely and inclined to each other.

However, the inlet and exhaust manifolds are on the different sides of the head. This arrangement provides better performance; however, it is costlier.

Advantages of detachable cylinder heads:

- Form the manufacturing point of view, the cylinder block casting with the open bore is much simpler to produce.

- Operations such as decarbonizing and valve grinding are easy to carry out.

- You can change the compression ratio slightly by changing the thickness of the head gasket.

Classification:

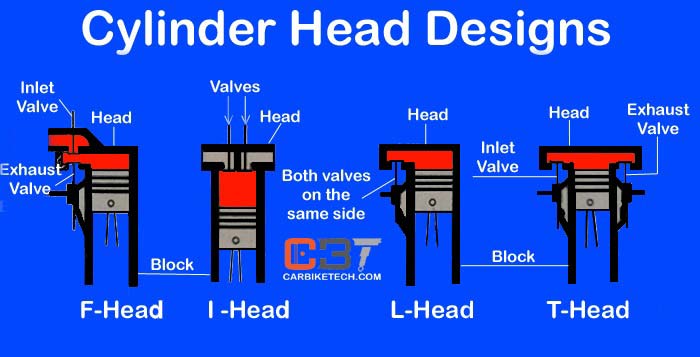

Furthermore, technically, cylinder heads are also classified according to the arrangement of valves. General classifications are “F” Head, “I” Head, “L” head, and “T” Head. In “L” head designs, both the inlet & exhaust valves are on one side of the engine and a single camshaft operates them.

However, the “I” head engines have the valves in the head which operate through push-rods and rocker arms. The “T” head engines have the inlet valves on one side and the exhaust valves on the other side which requires two camshafts. The “F” types have the inlet valve in the head and exhaust valve in the cylinder block and employ one camshaft.

Cummins, Detroit, Volvo, and MAN are some of the major engine manufacturers in the world.

Read more – What is Compression Ratio in engines?>>