Why Need A Steering System?

A proper steering system mechanism is necessary to effectively control the vehicle with safety during its entire speed range without much effort. It should also be able to tackle wide variations of road surfaces and bumps and bounces to the vehicle.

Moreover, it is the basic feature of the vehicle to be steered straight and maintained at that position or turned at the driver’s will without s/he putting much efforts to do so. It is also necessary that the moving vehicle is under driver’s perfect control in order to avoid an accident.

To control the vehicle properly, the driver should be able to:

- Turn the vehicle in different directions so that it does not go off course.

- Control its speed in order to move the vehicle as necessary.

- Slow it down or stop it slowly or suddenly without drifting.

The accelerator, gears, and brakes control the vehicle movement while the steering system provides directional changes to the moving vehicle. In addition to directing the vehicle in a particular direction, the steering system must be arranged geometrically. The wheels must roll freely without slipping or causing any friction. Besides, the steering must be light, stable, and with some degree of self-adjusting ability.

Steering mechanism must avoid tire slippage while the vehicle makes a turn. To achieve this, each wheel must roll on an arc which has a common center with the arcs of the other wheels of the vehicle. To make each front wheel move about its own pivot (around the kingpin or ball joints), it is necessary to turn the inner wheel through a larger angle than the outer wheel. This arrangement makes the two front wheels ”toe

Function:

The function of the steering system is to convert the rotary movement of the steering wheel into an angular turning of the front wheels. It also multiplies the driver’s effort by leverage or mechanical advantage so that it makes easier to turn the wheels. Steering knuckles carry the front wheels that run on the ball or tapered roller bearings. Hence, the steering system also must absorb some part of road shocks and prevent them from transmitting to the driver.

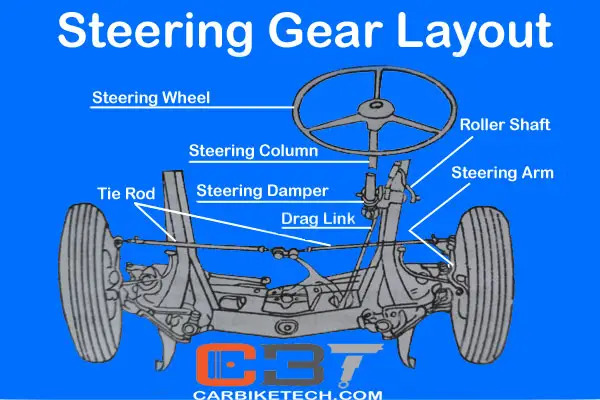

When the driver turns the steering wheel, it transmits the resulting motion to a steering tube. This tube rotates inside the steering column and transmits the motion further to the steering gear-set fitted at the end of the steering tube. Steering gear set changes the direction of motion and multiplies the twisting force according to the gear ratio. The output or roller shaft rotates and moves the

Components:

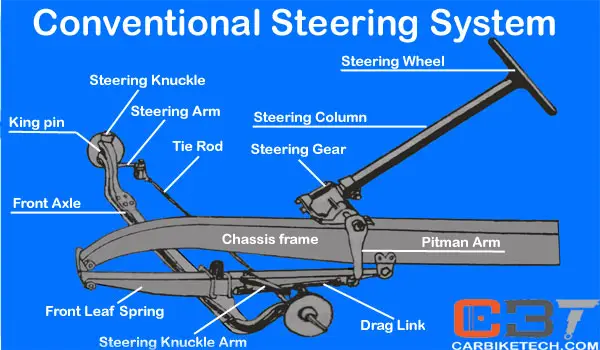

The conventional steering system has following components:

- Steering Gearbox

- Pitman arm

- Steering column

- Steering wheel

- Idler

arm - Track rod

- Steering Knuckle

- Tie rods

Steering system Operation:

vehicle steering system operates in the following way. When the driver makes a right turn,

- Both the steering wheel and steering tube turn clockwise; causing the steering gear to rotate the roller shaft

- This action moves the pitman arm’s bottom end forward and pushes the drag link.

- The intermediate steering arm which gets the push of the drag link moves the tie rods to the left.

- The right tie rod pulls the right steering arm and turns the right steering knuckle and right wheel to the right.

- The left tie rod pushes the left steering arm and turns the left steering knuckle and wheel to the right.

Similarly, for making a left turn, the above action will reverse.

Types of steering Systems:

Different vehicles have different types of steering gears. The types of steering gears depend upon the method of coupling the steering tube with the cross shaft. They are –

- Recirculating ball & nut

- Worm & roller

- Rack & pinion

- Worm & sector

- Cam & roller

- Worm & Ball Bearing

- Cam & peg

- Screw & nut

- Cam & turn lever

Moreover, the

Watch the steering system in action here:

Read more: What are types of independent suspension system in cars?>>