What Is Hydraulic Power Steering?

Power steering is necessary for most of the vehicles with increased demand for lighter control of the steering. Nowadays, Hydraulic power steering is a standard fitment in most vehicles. It provides lighter steering effort and easy maneuverability. Manufacturers employ power steering mainly to reduce the wheel turning efforts and to turn the sharp corners easily.

Power steering helps to negotiate the winding roads. It maneuvers the vehicle in confined spaces easily. It also offers some degree of resistance so that the driver gets the road feel and steering response. The road feel helps the driver to sense and predetermine the approach of front wheels. It visualizes the turning effort required to stabilize the vehicle body on turns, and in winds, etc.

Furthermore, to control a heavy vehicle with safety, particularly a loaded commercial vehicle, requires greater effort at the steering wheel. It should also be able to tackle wide variations of road surfaces and bumps and bounces. The use of large-section, low-pressure tires have greater road contact. So, they further magnif

Function:

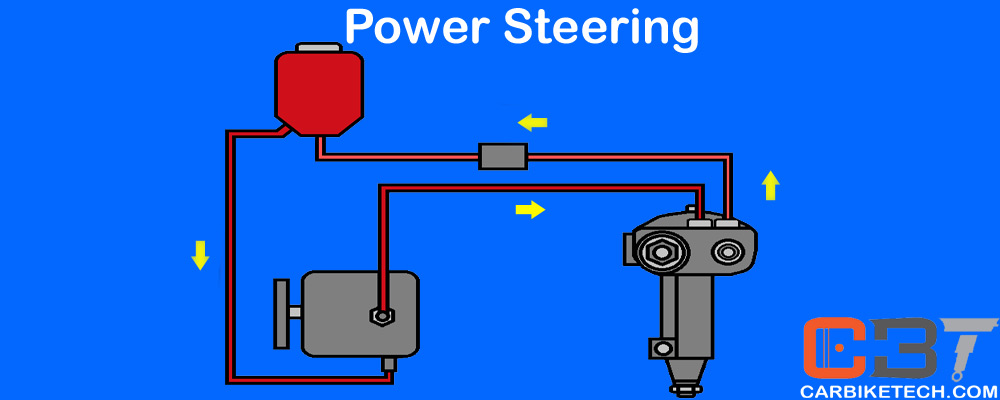

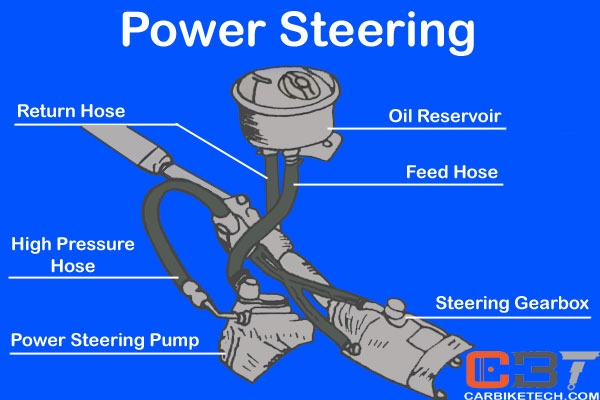

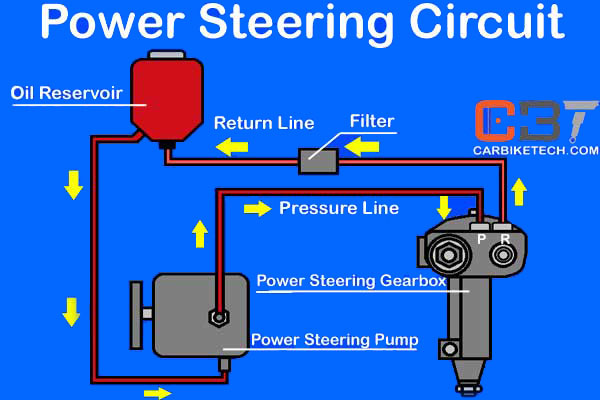

Hydraulic power steering system consists of a steering gearbox, and an oil pump, a valve. It also includes a double-acting power

Operation:

Most designs provide a booster arrangement to turn the steering wheel shaft. This booster mechanism takes care of most of the work of the steering. Power steering employs compressed air, electrical mechanisms, and hydraulic pressure to run the steering shaft. However, most vehicles use a hydraulic pressure operated steering mechanism. Different manufacturers developed different types of

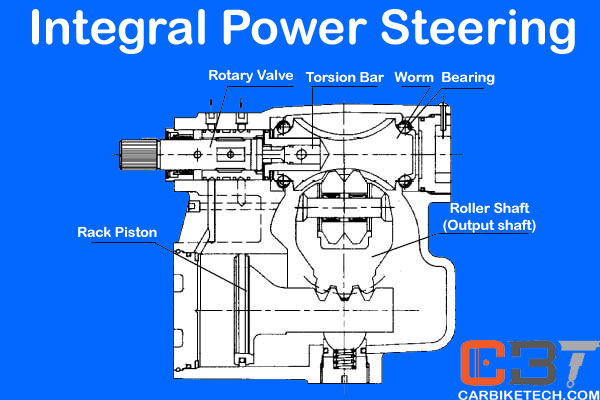

Generally, manufacturers use two types of power steering gears. They are – Integral and Linkage booster type. The integral type controls and uses the hydraulic pressure directly within the steering gearbox housing. However, the booster type employs a hydraulic cylinder and control valve with conventional steering gearbox.

Furthermore, Hydraulic Power Steering system uses a belt driven pump to produce the necessary hydraulic pressure. The steering effort of the driver actuates the control valve. It allows the pressurized hydraulic oil to enter one side of the hydraulic cylinder, thereby pushing the piston to the other side. This causes the piston to move and forces the Pitman arm to the steering linkage and thereby the wheels.

Types of Hydraulic Power Steering Gears:

Nowadays, Power steering uses either hydraulic pressure or electric power assistance (epas) to operate the steering gear. Titan, ZF, and Rane are some of the leading manufacturers of steering gear components in the world.

Watch the Hydraulic Power Steering system in action:

Read More: What is Volvo Dynamic Steering?>>