Which are the types of car pillars?

The structure of an automobile body is just the same as that of a house. It has similar components, including the roof, pillars, and floor. The car pillar in the vehicle stands in the near-vertical position, which supports the vehicle’s roof. However, the A-pillar and the D pillar stand inclined in some vehicles for aerodynamic reasons.

Furthermore, the manufacturers identify the car pillars from the side while moving from front to rear of the vehicle. They name the car pillars the A-pillar, B, C, and D pillars. The vehicle designers sometimes refer to the car pillars as ‘posts.’

Why call them the A/B/C/D Pillar?

The naming system adopted for the pillars may have possibly been originated from their shapes as seen from sides. The A-pillar resembles the shape of the alphabet “A.”

The other pillars resemble “B,” “C,” and “D” letters, respectively. Is it a mere co-incidence or designer’s creativity? For example, if the vehicle has a stretched body structure with additional doors, such as a limousine, it gets more than one B pillars. In these cases, manufacturers name them B1, B2, B3 & so on while moving from front to rear. For example, rescue teams communicate the names of pillars (A/B/C/D) while cutting the pillars with cutters. Hence, the naming of pillars is important while rescuing the passengers trapped in accident-damaged vehicles.

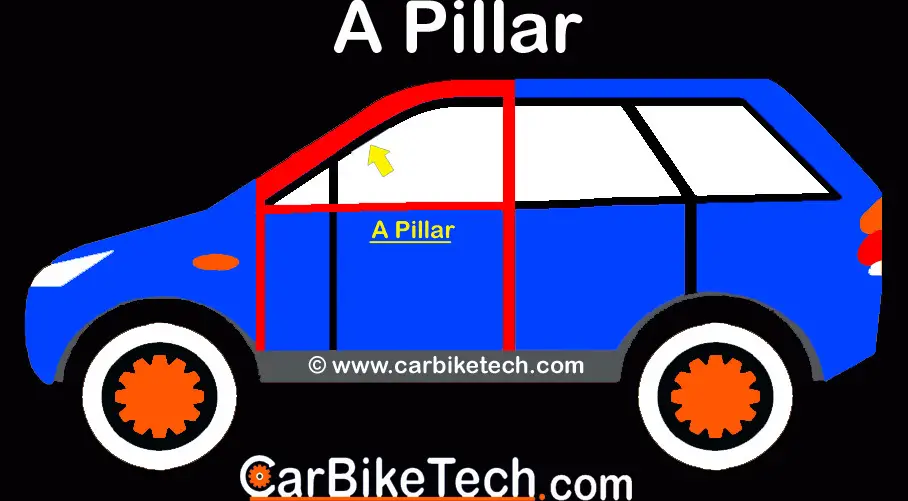

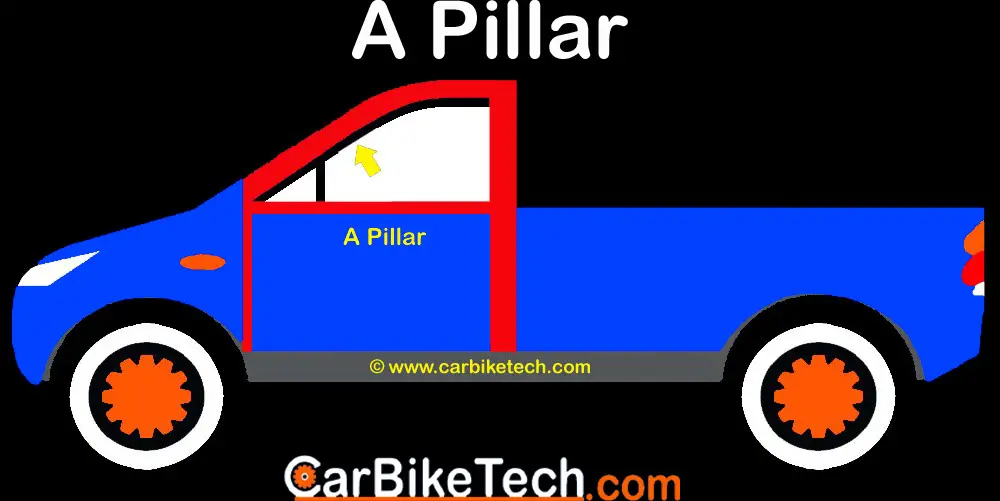

Purpose of the Car Pillar A:

Manufacturers provide the A-pillars on both sides of the vehicle. Manufacturers use strong steel alloys to make the A-pillar. Thus, it is to make it withstand a crash and meet safety standards. However, the vehicle’s roof and doors are the most expensive parts to carry out repairs. In addition, the blind spot occurs due to the blocking of the driver’s vision by the A-pillar. So, some makers make the A-pillar slimmer and chamfered to decrease the blind spots. And, thus it improves the driver’s vision.

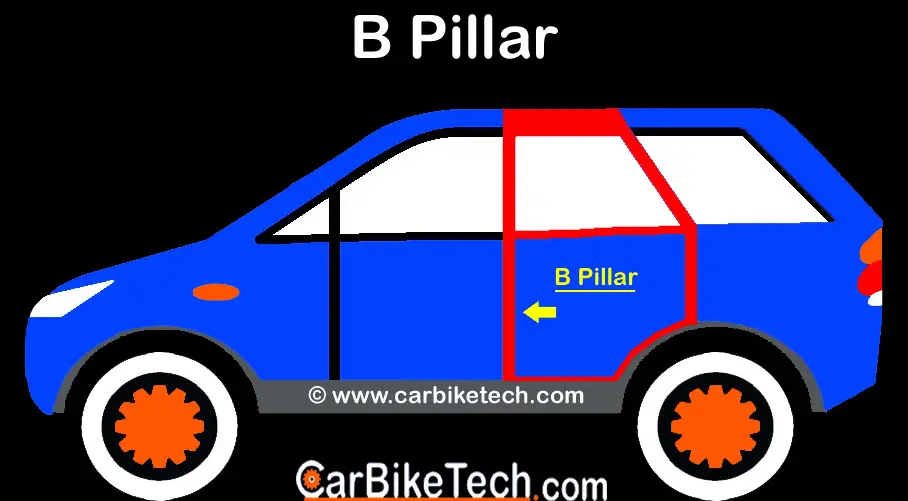

B Pillar:

Furthermore, B Pillar is the most complex component/structure of the vehicle body. It is because the front door closes on the B pillar while the rear door hinges on it. Manufacturers make the B pillar or the center pillar of steel in vehicles. Manufacturers weld it to the roof panel on top and the vehicle’s floor pan at the bottom. This pillar provides structural support to the vehicle’s roof.

Manufacturers skipped the B pillar while naming other pillars. Hence, some vehicles do not have a B Pillar. The carmakers call those cars ‘Hardtops.’ Instead, the vehicle specification shows the rearmost pillar as the C pillar. The manufacturers offer the Hardtops in nearly all four-door body styles. These include sedans, coupes, and wagons/MPVs. The cars without B pillars increase passengers’ visibility. However, they have limited structural support and strength. General Motors later started providing B pillars in Hardtops. Thus, it created a new vehicle body type and thereby broadening the definition of Hardtops.

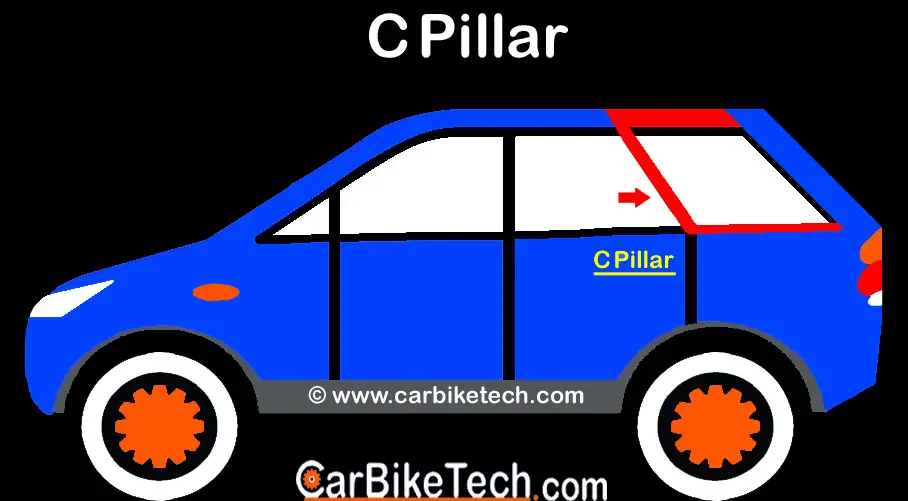

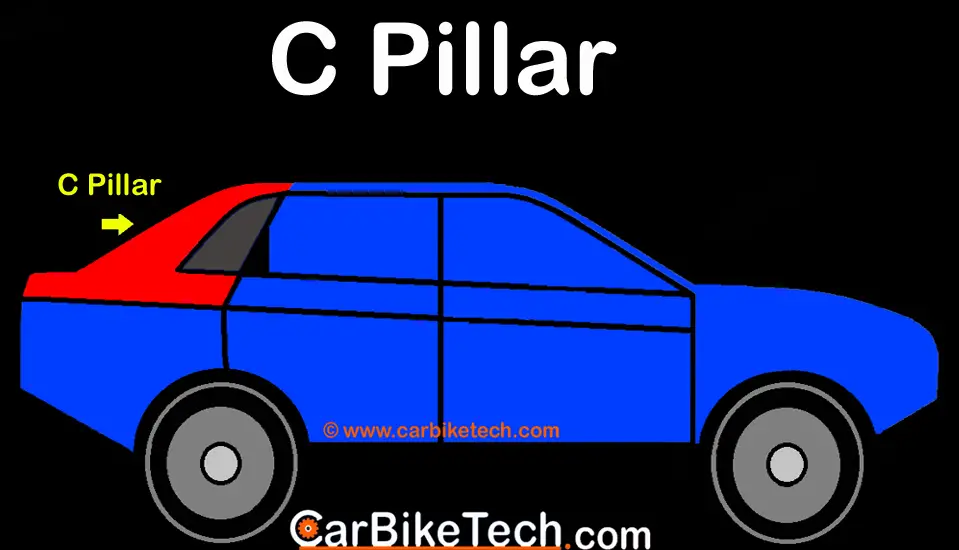

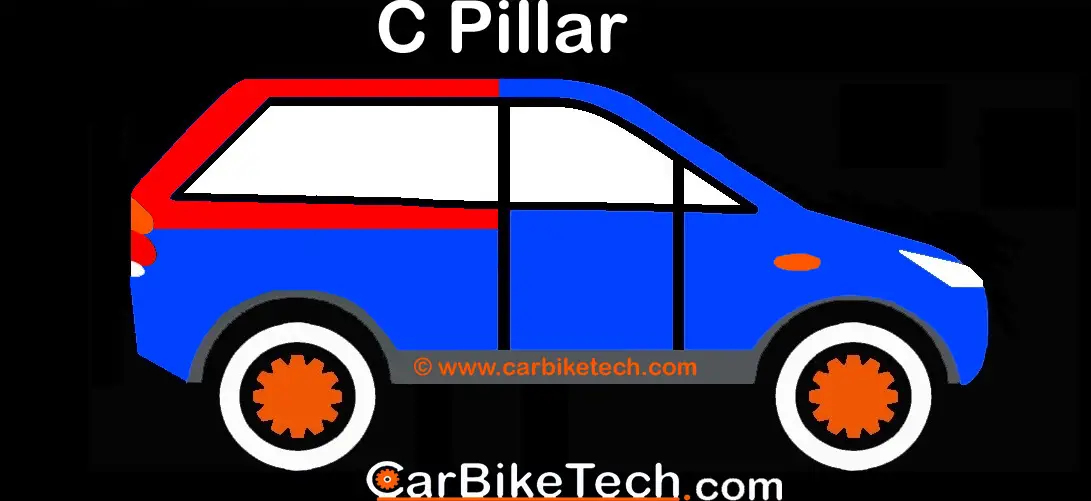

Car Pillar C:

The C pillar sits behind the rear door.

However, the C pillar is the rearmost pillar in sedans and hatchbacks.

C Pillar of a Hardtop

C Pillar of a Hardtop

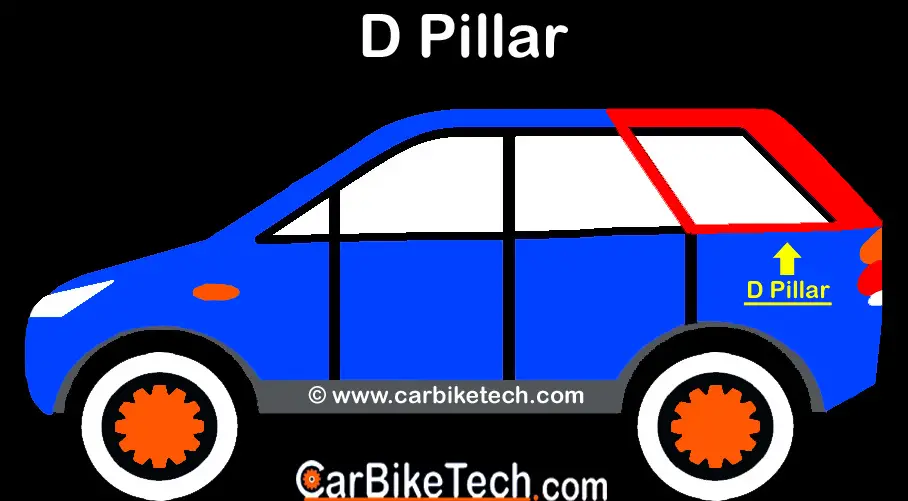

D Pillar:

Technically, the D pillar is the rearmost pillar of the vehicle’s body. However, manufacturers provide the D pillar mainly for the Station Wagons or Multi-Purpose Vehicles.

Repairing the Car Pillars:

Like the house, the vehicle pillars carry the roof’s weight and support the vehicle’s body structure. The pillars provide structural strength to the vehicle’s body. So, repairing the vehicle’s body is a very critical process. Any unauthorized modifications to the pillars could jeopardize the vehicle body’s structural strength and, thereby, the safety of the passengers. Hence, one needs to take care while repairing any part of the car pillar.

Manufacturers provide specifications to maintain the critical dimensions and detailed procedures while carrying out any repairs on the vehicle body, especially the pillars. Therefore, only trained and skilled mechanics could precisely carry out the car pillar’s modifications.

However, some manufacturers do not recommend repairing the car roof in severe damage due to an accident. In such situations, they recommend replacing the complete body shell if it is beyond repair. In such cases, carrying out repairs of the roof may reduce its structural strength to a large extent. Thus, it may make the vehicle unsafe and underperform.

To carry out the vehicle body’s structural repairs, you need specialized equipment such as the repair bench, five-dimensional fixture sets, a pulling arm, and a three-dimensional electronic laser measuring system. These are necessary to maintain the vehicle body’s critical dimensions and structural strength.

Watch vehicle body Car Pillar repairing in action here:

Please click here for more information on the correct vehicle body repairing practices.

Read more: What is the weight Loss Therapy for cars? >>