Recirculating Ball Nut Steering Gear:

The Recirculating Ball Nut is a steering mechanism that is generally found in the earlier generation cars. It is also used in some off-road vehicles and especially in trucks. However, the newer generation cars mainly have the ‘Rack and Pinion‘ steering mechanism. Manufacturers employed the recalculating ball mechanism in the 1990s for its durability of the design and strength.

What is Recirculating Ball steering?

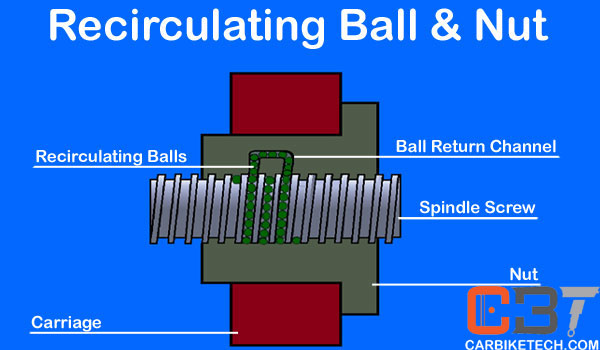

The recirculating ball nut steering system is very similar to the worm & nut mechanism. It has helical grooves on the steering gear (worm). It also has the corresponding grooves on the nut. The steering gear and nut are bridged by the small steel balls. These steel balls help to reduce friction. Besides, these balls can roll in and out and recirculate in a loop system. As the driver rotates the steering, the steering column turns the worm gear on the end of the shaft. It moves the recalculating the balls and causes the steering linkage to move.

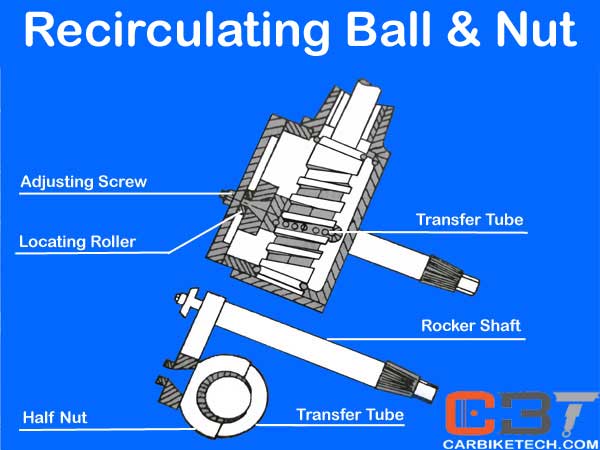

The recirculating ball nut steering gear is an improved form of worm & nut mechanism. It has a nut with steel balls acting as threads which provide higher mechanical efficiency of 90%. The recirculating ball mechanism has a half nut and transfer tube that contains the balls. It feeds the balls back to the nut by employing the half nut with the transfer tube. A peg of the nut is located in the rocker arm.

The balls pass from one side by rotating the cam of the worm. Any movement of the balls along the track of the cam carries the nut along with it because the nut cannot turn. This movement causes the rocker shaft to rotate. The recirculating ball nut steering gear is quite efficient because the frictional losses are minimal. The chances of failure of this type of steering are almost none.

How this steering mechanism works?

The Recalculating Ball Nut steering shaft has the worm on its lower end while the nut is mounted on the worm. Both the worm & nut have mating spiral grooves in which the steel balls circulate. This provides a frictionless drive between the worm & nut. Besides, this mechanism uses two sets of balls which operate independently of each other. Each set of balls circulates thru’ a circuit. It includes the grooves in the worm and the nut & the ball-return guide attached to the outer surface of the nut. When the driver turns the steering wheel to the left, it moves the steering shaft.

The balls, which roll between worm & nut, also move the ball nut downwards. As the balls reach the outer surface of the nut, they enter the return guides which guide them across & down into the ball nut where they again enter the circuit.

Furthermore, when the driver takes the right turn, it causes the ball nut moves upward. This causes the balls to circulate in the reverse direction. Teeth on the ball nut engage the teeth on the sector gear (pit-man arm) forged integral with pitman arm or cross shaft. So, when the ball bearing nut moves up or down the shaft, its teeth move the sector teeth & force the cross shaft to rotate.

ZF, Rane TRW, & SKF are some of the leading manufacturers of Recirculating Ball Nut steering gears in the world.