About The Automatic Transmission:

An automatic transmission is a type of transmission or gearbox that can automatically change the gears while the vehicle is in motion. Manufacturers also term it as just the Auto or AT, the Self-shifting transmission. It is also known as the ‘n-speed’ automatic, where ‘n’ is the number of forward gear ratios. It is a type of motor vehicle transmission that frees the drivers from shifting the gears manually or by themselves. In vehicles with automatic transmission, there is no clutch pedal. The driver can control the car only thru’ the accelerator and brake.

How An Automatic Transmission works?

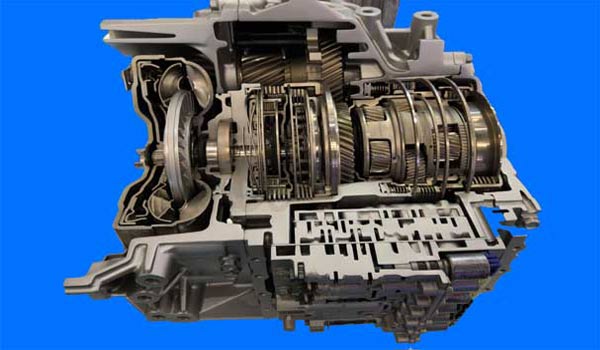

The most popular type of automatic transmission in automobiles is the hydraulic type. However, heavy-duty commercial and industrial vehicles use similar but larger devices. The automatic transmission uses a fluid coupling in place of a friction clutch. It drives the gear changes by hydraulically locking and unlocking the planetary gears.

So, an automatic transmission has a definite set of gear ranges. It often comes with a parking brake that locks the transmission’s output shaft. Thus, it keeps the vehicle from going forward or backward when parked. Some vehicles have limited speed ranges or stable engine speeds, such as forklifts and lawnmowers. Such vehicles use only a torque converter to provide the variable speed of the engine to the wheels.

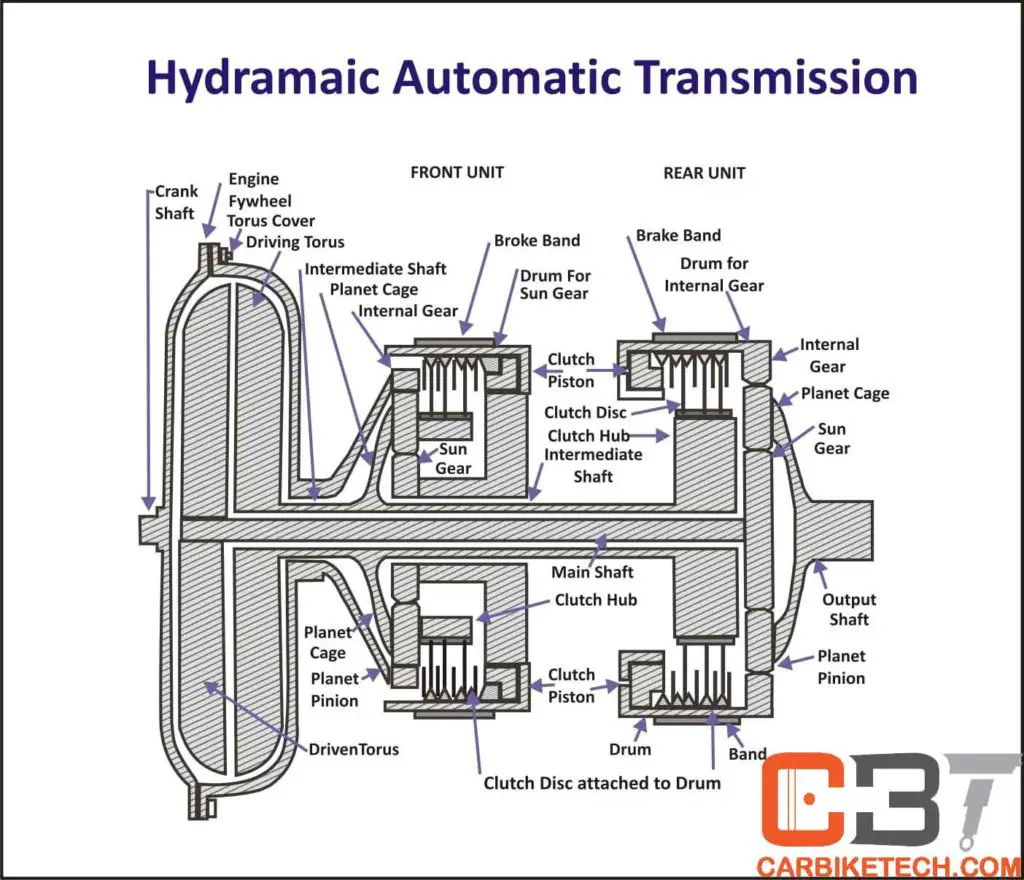

Hydramatic Transmission:

It is a fully automatic type of transmission. The Hydra-Matic drive combines the automatic four-speed forward and reverse-geared transmissions. Besides, it uses a fluid flywheel such as the fluid coupling or the torque converter for the purpose. The geared transmission consists of three sets of constant-mesh helical planetary gears in series. Two sets of the planetary gears provide four forward gear ratios while using the other set for reverse. The fluid flywheel cushions the impact of automatic gear shifting and reduces the engine’s torque reactions.

Components Of An Automatic Transmission System:

The primary type of automatic transmission operates hydraulically. It uses a fluid coupling or torque converter and a set of planetary gears to provide a range of gear ratios. The Hydraulic automatic transmissions consist of three major components. They are – Torque converter, planetary gears, and hydraulic controls.

Torque Converter:

The Torque converter is a type of fluid coupling. It connects/disconnects the engine hydraulically to the transmission. Besides, the torque converter replaces the friction clutch in a manual transmission. It connects and disconnects the engine power to the planetary gears. Thus, it allows the vehicle to come to a stop without stalling the engine. Furthermore, it offers a variable amount of torque multiplication at low engine speeds. So, it increases the breakaway acceleration. A fluid coupling works well when both the impeller and turbine rotate at the same speeds. However, it is very inefficient at the initial acceleration, where rotational speeds are pretty different.

The torque converter is similar in construction to that of a fluid coupling. It increases torque to the transmission input shaft at low engine speeds. It falls off to the engine torque value at a particular engine speed because it’s becoming inactive. The torque converter consists of an engine driver impeller and a turbine converted to the gearbox input shaft. It also has a small vane wheel called a stator between the impeller and the turbine.

How Torque Converter Works?

Thus, it maximizes the torque multiplication with the stator, which modifies the fluid flow depending on the impeller and the turbine’s relative rotational speeds. The stator itself does not rotate. However, manufacturers shape their vanes so that when the impeller rotates at high speed, the turbine spins at a low speed. The fluid flow hits the vanes of the turbine to multiply the torque it applies. Thus, it causes the turbine to spin faster as the vehicle accelerates. However, the torque multiplication reduces when the relative rotational speeds become equal. After the impeller and turbine rotate within 10% of each other’s speed, the stator stops functioning, and the torque converter acts as a simple fluid coupling.

Planetary Gear Train

The planetary gear train consists of sets of planetary gears. It also has clutches and bands which provide various gear ratios. They alter the speed of the output shaft depending on which the driver engages the planetary gear. The gearbox uses one of the two types of clutches or bands to effect the gear changes. Besides, it holds a particular member of the planetary gear set motionless while allowing another member to rotate. Thus, it transmits the torque and offers either reduction or overdrive ratios. A valve body actuates these clutches while the automatic transmission’s stock program controls their sequence.

Primarily, the automatic gearbox uses a roller clutch for routine upshifts/downshifts. It operates just like a ratchet. It transmits the torque only in one direction by free-wheeling or overrunning in the other. The advantage of this type of clutch is that it eliminates the possibility of simultaneously applying the clutch release on two planetary gears. Thus, it takes up the drivetrain load when actuated and automatically releases when the next gear’s clutch assumes the torque transfer.

The bands become active for manually selected gears, such as low range or reverse, and operate on the planetary drum’s circumference. Bands are not applied when the gearbox drive/overdrive range is selected. Instead, the clutches transmit the torque. However, some cases use bands for braking.

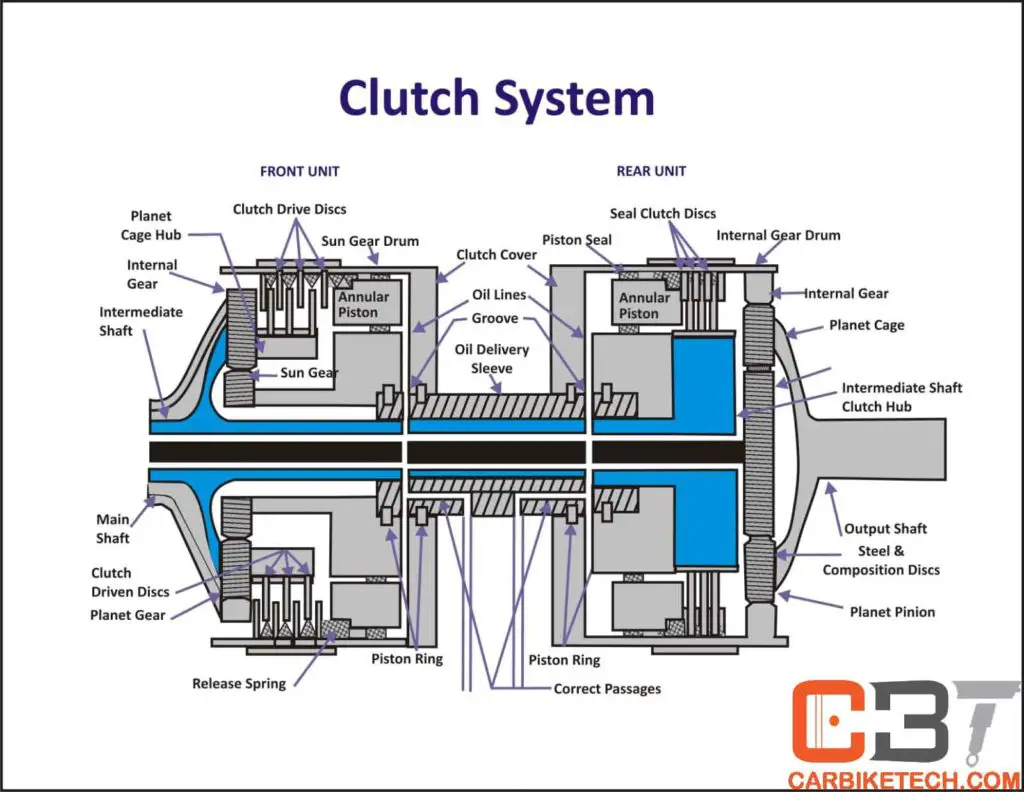

Clutch System:

Each unit comprises a multiple-disc clutch for locking gears in direct drive. The front unit has two steel plates or discs splined to the sun-gear drum to form a direct drive unit. It also has three or more composition discs spaced alternatively between the steel discs. These are splined to the planet cage hub and form the driven part of the clutch. The rear clutch is similar in construction. Except, it contains more clutch plates. Besides, the steel plates or discs fasten to the internal gear drum. Steel and composition discs spline to the intermediate shaft hub. Same as the drum, the clutch discs are circular in shape.

When you apply either clutch, an annular piston forces the two sets of clutch discs into contact. Thus, it makes them revolve together as a single locked unit. The oil pressure, supplied thru’ controls, operates the piston and acts as a pressure plate in a mechanical clutch. The clutch application locks the sun gear and the planet cage in the front unit. However, the clutch locks the internal gear drum to the intermediate shaft hub in the rear unit. Two passages thru’ the transmission case provide the clutches with hydraulic pressures for operating the annular pistons. They lead from the valve controls to the oil delivery sleeve.

Makers Of Automatic Transmission Systems:

BorgWarner, Cummins, and ZF are some of the world’s leading manufacturers of automatic transmissions.

Common Automatic Transmission Modes:

P – P stands for Parking. With this selection, you can mechanically lock the transmission’s output shaft. Thus, it restricts the vehicle from moving in any direction. However, the vehicle’s non-driven wheels that are still free, can rotate. The driven wheels may also spin individually because of the differential action. Hence, you should always use the hand brake (parking brake) as it locks the wheels and prevents them from moving.

R – R stands for Reverse. It engages the reverse gear of the automatic transmission, permitting the vehicle to drive backward. To select reverse in most transmissions, you must come to a complete stop, depress the shift-lock button, and select reverse.

N – N stands for Neutral or No gear (N). It disengages all gear trains within the transmission. It effectively disconnects the transmission from the driven wheels, allowing the vehicle to coast freely under its own weight and gain momentum.

Driving Forward:

D – D stands for Drive mode. This position allows the automatic transmission to employ the full range of available forward gear ratios. It enables the vehicle to move forward and accelerate through its range of gears.

[D] – The [D] stands for Overdrive. Some transmissions use this mode to engage the automatic Overdrive. In these transmissions, Drive (D) locks the automatic Overdrive off. As a result, the OD (Overdrive) engages under steady speeds or low acceleration at approximately 35–45 mph (56–72 km/h). However, under hard acceleration or below 35–45 mph (56–72 km/h), the transmission automatically downshifts.

L/1 – L stands for Low gear. This mode locks the automatic transmission in first gear only. In older vehicles, it will not change to any other gear range. Some vehicles will automatically shift up out of first gear in this mode to prevent engine damage if it reaches a specific RPM range.

Depending upon the manufacturer and model, there are other modes as well. These include:

D5 – Cars having five-speed automatic transmissions commonly use this mode for highway use. It uses all five forward gear ratios.

D4 – Cars having four or five-speed automatics only use the first four gear ratios. It is used primarily for stop-and-go traffic, such as city driving.

D3 or 3 – Cars with four-speed automatics only use the first three gear ratios. However, people primarily use it for stop-and-go traffic, such as city driving.

D2 and D1 – Older Ford cars used these modes. D1 uses all three gears are, whereas, in D2, the car starts in second gear and upshifts to third.

S or Sport

S commonly stands for Sport mode. It operates identically as “D” mode. However, the upshifts change at a much higher engine’s rpm. It maximizes the engine output and enhances the vehicle’s performance, mainly during acceleration. This mode also downshifts at a much higher RPM than the “D” mode and maximizes engine braking. However, this mode results in a lower fuel economy.

Some Modern Vehicles Also Offer Some More Modes Such As:

+ −, and M

M stands for the Manual mode selection of gears in certain automatic vehicles. However, some cars do not have ‘M.’ Instead; they have ‘+’ and ‘-.’ Thus, it separates from the rest of the shift modes. The driver can shift up and down at will by toggling the shift lever like a semi-automatic transmission. You can engage this mode either through a selector/position or by actually changing the gears by tilting the gear-down paddle-shifters on the steering wheel.

Winter (W)

Some models also offer a winter mode. It engages the second gear instead of the first when pulling away from stationary. It reduces the loss of traction due to wheel spin on snow or ice.

Brake (B)

B stands for Brake mode that some models, including electric cars, offer. You can use it to decelerate or maintain downhill speed without using the car’s brakes. In non-hybrid cars, B mode selects a lower gear to increase engine braking. In electric, B mode increases the level of regenerative braking when you release the accelerator pedal.

Watch Automatic Transmission In Action Here:

Read on: What are the driving modes? >>