Gearbox Working Principle:

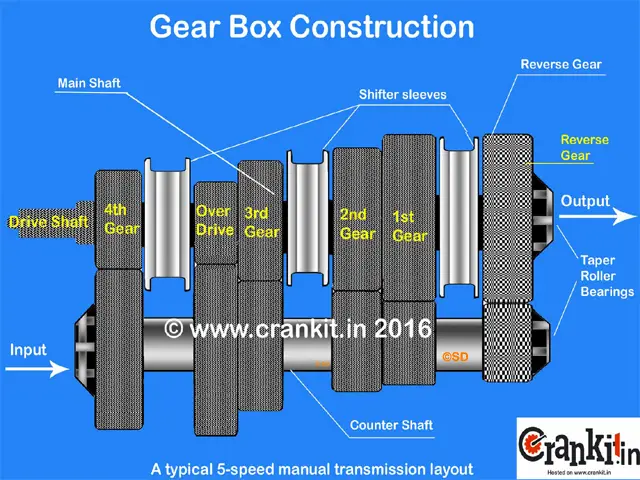

A gearbox comprises various gears, synchronizing sleeves, and a gear-shifting mechanism fitted inside a metal housing. The metal housing, usually made of aluminum/iron casting, accommodates all the gears. The gearbox is a part of the ‘transmission’ system. The gears play an important role in transmitting the engine power to the wheels.

What is Transmission?

All the drive-train components that help transmit the engine power to the wheels are a part of the ‘Transmission’ system. Of which the gearbox is an integral part. These components include the clutch, gearbox, couplings, propeller shaft, axle shafts, and differential. In general, ‘Transmission’ usually refers to the car’s gearbox. However, some car designs integrate the gearbox and differential assembly into a single unit called ‘Transmission’ or ‘Trans-Axle.’

What is the Gear Ratio?

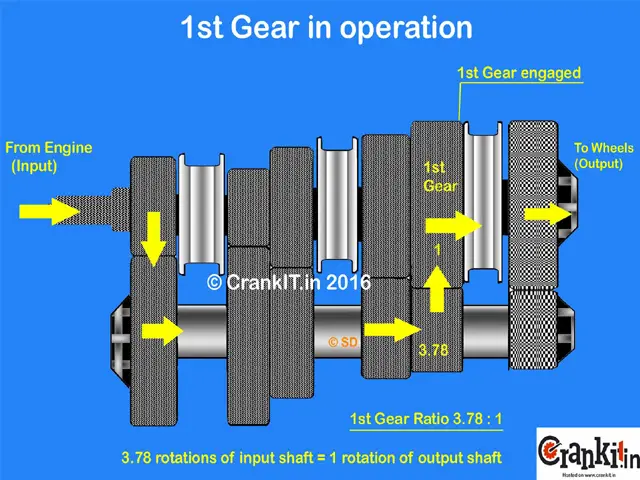

The gear ratio is the ratio between the input and output gears. The driving gear and driven gears in a gearbox define the gear ratios. The input gears get the engine’s drive and rotate the output gears, which, in turn, drive the wheels. The ratio of the number of rotations of output gear to the number of rotations of input gear is called the Gear Ratio.

The following formula Can Also obtain the Gear Ratio:

Gear Ratio = No. of teeth of output gear / no. of teeth of the input gear

E.g., If no. of gears on input (driving) gear = 30, no. of gears on output (driven) gear = 105

Then, the Gear ratio = 105/30 = 3.5:1 because to rotate the output (driven) gear by 1 rotation, you need to turn the input (driving) gear by 3.5 rotations.

A typical chart of Gear ratios in a gearbox of a MUV:

Following is a chart of gear ratio found in a MUV’s gearbox.

|

Gear |

Ratio |

| 1st gear |

3.78:1 |

| 2nd gear |

2.20:1 |

| 3rd gear |

1.42:1 |

| 4th gear |

1:1 |

| 5th gear (Overdrive) |

0.83:1 |

However, the gear ratios vary from vehicle to vehicle. For example, the gear ratios are typically higher than cars in trucks as they carry a heavy load.

How does a Gearbox work?

A gearbox contains gears of different sizes. It is mainly because of the vehicle’s varying demands for the torque required at the wheels depending upon the road, terrain & load. E.g., if a vehicle is climbing a slope, it needs higher torque than cruising on a straight road.

Furthermore, the first gear is the biggest in a gearbox and provides maximum torque output while producing minimum speed. Hence, the drivers use it when climbing slopes. All the gears between 1st and last gear vary in size, in a decreasing ratio. Thus, it provides a varying combination of pulling ability and speed. So, you could drive the vehicle smoothly without any drop in its acceleration. The gearbox, basically, improves the vehicle’s driveability in all conditions.

What is an Overdrive?

In contrast, the last gear or the top gear, at times an Overdrive, is of the smallest size. However, it provides minimum traction but maximum speed. A gearbox with an Overdrive means its output is higher than its input that connects to the engine. In other words, the overdrive gear rotates faster than the engine speed. Thus, it provides higher speed and better efficiency as the engine runs at a lower rpm in relation to the vehicle speed.

Moreover, there is more than one ‘Overdrive’ gear in some advanced designs, usually two. Thus, Dual Overdrive (aka ‘Double Top’) provides even higher speed and better efficiency in a vehicle.

Gearbox Operation:

Generally, there are two sets of gears in a conventional gearbox – the input & the output. The input gears are fixed on the countershaft, making them single units. It drives the individual gears on the main shaft, which rotate freely on the bearings. Thus, the gearbox passes the drive to the wheels depending upon the gear which engages on the main shaft. Furthermore, when you push the shifter sleeve towards the desired gear, that gear locks onto the main shaft and rotates it. Thus, the main shaft rotates at the engaged gear’s speed and provides the output according to the engaged gear’s ratio.

Gearbox: Speed vs. Traction

Basically, you need both speed and traction while driving an automobile. The gears in the gearbox help you choose either of them, depending on the driving conditions. The lower gear, i.e., 2nd and 1st gear, will give you the most excellent traction, while the higher gears, i.e., 5th and 6th (if available), would give you the highest speed. Furthermore, the number of gears in the gearbox provides the perfect combination of traction and speed. Thus, it helps the driver/rider choose the most appropriate combination to enhance efficiency. Hence, selecting the right gear according to road and load conditions is very important. You get better acceleration or pick-up with short gearing, while tall gearing gives you higher top speed.

Types of Gearbox:

In general, there are mainly four categories of an automotive gearbox:

- Manual – With up to 6 forward gears in a car and up to 13 forward gears in a truck.

- Fully Automatic Transmission – up to 10 speed.

- Continuously Variable Transmission – CVT.

- Automated Manual Transmission (AMT) – up to 5 speed.

- Dual Clutch Transmission – (DCT).

According to the shifting mechanism, manufacturers further classify the automotive gearboxes into three more categories:

- Sliding mesh – typically used in two-wheeler/bikes

- Constant-mesh – typically used in old-generation trucks

- Synchromesh – used in the newer generation cars & trucks

According to the shifting mechanism’s location:

- Column Shift – Gear lever mounted on the steering column, operated by hand.

- Floor Shift – Gear lever mounted on the floor, operated by hand

- Paddle Shifters – Gear-shifters fitted on the steering wheel, operated by fingers.

Besides, Eaton and ZF are some of the reputed gearbox manufacturers in the world.

For more information on the newer generation gear boxes, click here.

Watch How A Gearbox Works Here:

Read more: How torque helps to improve efficiency in a vehicle?>>