What is a CVT?

CVT stands for Continuously Variable Transmission. It is an advanced type of gearbox and part of many modern-day cars. As the name suggests, it varies the speed continuously instead of step-by-step as in an automatic gearbox. As a result, it makes the drive smoother than other transmission types. Basically, Continuously Variable Transmission is a type of automatic transmission. However, even without driving the vehicle and just looking at the gear lever, you will notice it is the same as a conventional automatic. It does the same thing as the automatic gearbox. It automatically converts the engine’s limited speed range to various ratios and sends it to the driven wheels using several different gears.

The main difference between the automatic transmission and CVT is the number of gears. The automatic gearbox is limited to 4 to 9 gear ratios. Besides, there are definite or noticeable changes between the gears, and you could feel this during driving. However, CVT has an infinite number of ratios ranging from low to high. It is because the transmission moves ‘steeplessly’ through the gears according to the driving conditions. Even though manufacturers use the term infinite, the lowest ratio is close to the first gear in an automatic gearbox.

In contrast, the highest ratio is close to the highest gear in a standard gearbox. Not all continuously variable transmissions are the same. Some are designed for economy hatchbacks & sedans, while others are for vehicles with more powerful engines.

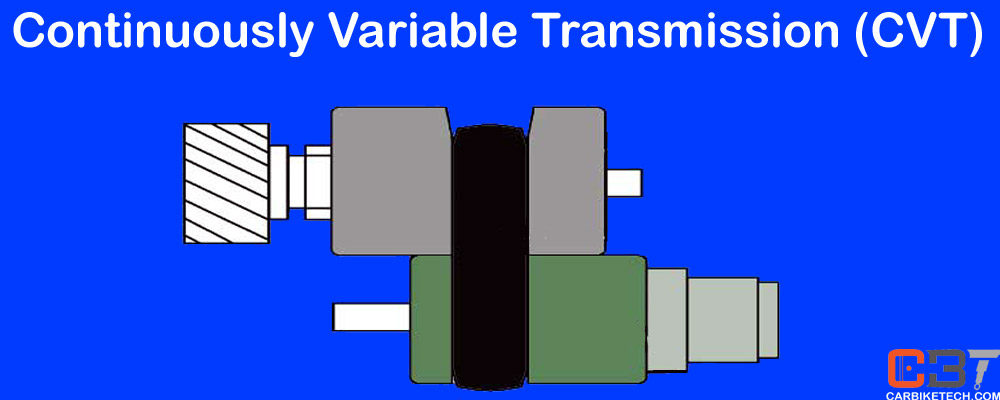

Continuously Variable Transmission is simple in design with a few components comprising of these parts:

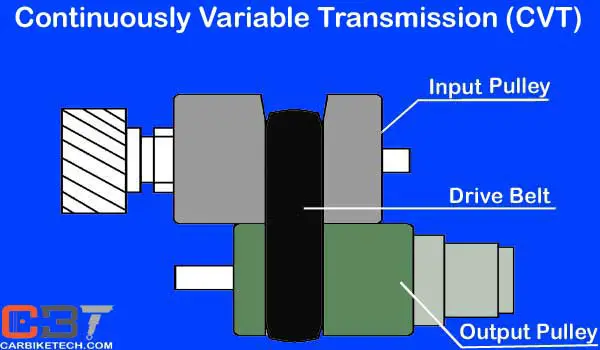

- 2 Pulleys – a variable input pulley that spins from the power from the engine

- An output pulley that sends the power to the driven wheels.

- A high power/density rubber or metal belt connects the 2 pulleys and varies the ratios between them as the vehicle is being driven.

- Various microprocessors and sensors as the transmission must be able to detect the driving conditions.

How does CVT work?

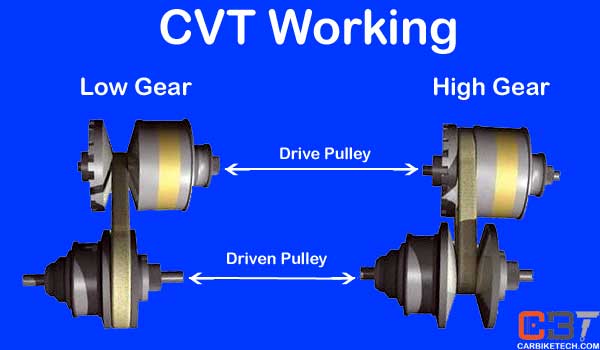

A Continuously Variable Transmission (CVT) is also known as a single-speed transmission, step-less transmission, or pulley transmission. This automatic transmission can change seamlessly through a continuous range of effective gear ratios. Thus, it differs from other mechanical transmissions that offer a fixed number of gear ratios. The flexibility of a CVT allows the input shaft to spin at a constant angular speed.

Moreover, CVT consists of two conical pulleys and a metal or rubber belt or chain. Input pulley turns the belt which, in turn, rotates the output pulley. The gap between the cones regulates the effective diameter of the pulleys. As & when this gap reduces, the effective diameter of the pulley increases. When the right-side cone of the input pulley moves to the right and the left-side cone of the input pulley also moves to the right, it makes the input pulley bigger than the output pulley. Thus, the output is greater than the input, making it the overdrive.

Besides, the transmission control unit adjusts the width between the cones according to driving conditions. As a result, the change in speed is gradual, smooth, and unnoticeable. For reverse gear, manufacturers provide planetary gear mechanisms in CVT.

Watch CVT Working Here:

Advantages:

Furthermore, Continuously Variable Transmissions deliver better fuel economy by allowing the engine to run at its most efficient RPM for any engine speed range. In addition, vehicles with CVTs drive smoothly as the passengers don’t feel any jerks from gear changes. An improved fuel economy and a smoother ride for passengers are the main benefits of CVT.

- CVTs are really very smooth to drive.

- Great fuel efficiency than conventional automatic gearbox in city driving and also on the highway.

- No power loss.

Disadvantages:

- They tend to make the engine rev to red-line on highways before shifting, and the resulting noise is awful.

- In addition, CVTs are expensive to buy.

- High Maintenance costs as they require more transmission fluid changes compared to a generic automatic gearbox.

- The belt (if used) limits the transmission’s torque transmitting capacity.

Furthermore, many car manufacturers employ CVT in their cars. Some popular cars with CVT are Honda Jazz, Honda City, Hyundai i20, Nissan Micra, Toyota Yaris, Renault Duster, MG Hector, Kia Seltos, and Toyota Camry. In addition, premium cars such as Audi A4, Mercedes-Benz A-Class, and Lexus also employ Continuously Variable Transmission in some of their car models.

In conclusion, CVTs offer better fuel economy, excellent driving convenience, and more passenger comfort. They are great, especially in the city driving conditions. However, all these qualities come at a cost as they are expensive to buy and use.

Watch CVT In Action Here:

Read More: What is VVT?>>