VVT stands for Variable Valve Timing:

Let’s try to understand in the begining, why to vary the Valve Timing/VVT?

Firstly, read here first what is ‘Engine valve-timing’? An automotive engine actually ‘breaths’ (inhales/exhales) thru’ its valves just like the humans do. The rate at which humans breathe mainly depends upon the work carried out by humans. For e.g., if the person/s are sitting or sleeping, they will breath slowly as compared to when they are walking or running. Besides, while carrying out activities like swimming or lifting a weight the persons also need to open the mouth to get more air.

This is because when the human body is subjected to heavy work, it increases the need for air-intake. Thus, it causes faster breathing and/or wider opening of the mouth to receive more air. Similarly, when the engine runs at high speed; it needs to open its inlet valves earlier, faster & for a longer period. This is because to produce more power, it needs to suck more air-fuel mixture (charge) for burning.

In older conventional engines, the time for which the valves remained open was optimised only for single engine speed. However, as the engine speed increases, it considerably reduces the time required to fill the cylinders fully.As a result, the engine would receive less amount of charge (air-fuel mixture) which causes power-loss especially when the engine runs at high speed.

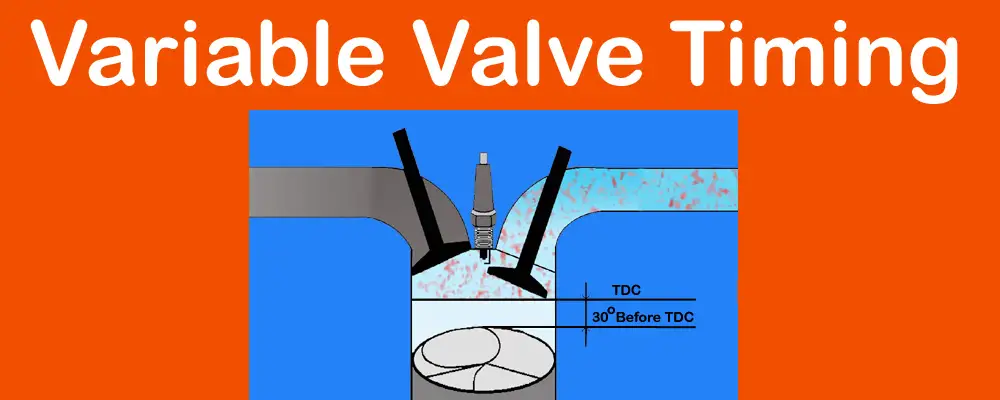

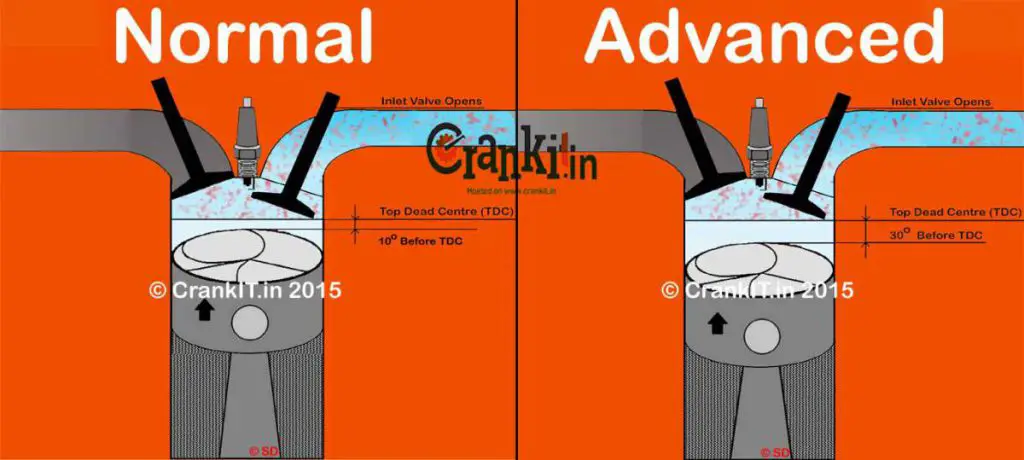

To overcome this deficiency, the engineers developed VVT or ‘Variable Valve Timing’ mechanism. The VVT varies the timing of opening and closing of valves for multiple engine speeds. At high speed, the Inlet valves open quite earlier so that more air-fuel mixture or ‘charge’ enters the cylinders. This helps to increase engine’s breathing which also improves its ‘volumetric efficiency’ to a large extent.

How VVT Works?

The Variable Valve Timing system further optimizes the timing of opening and closing the valves for multiple engine speeds. The first-generation VVT design uses two-step variation which optimises the engine for two different engine speeds. This design enables two different set of timings which includes one for the ‘part-load’ condition i.e. upto 3500 rpm and other for the ‘full-load’ condition, i.e. above 3500 rpm. In addition, VVT more often improves performance and reduces emissions. Besides, VVT also provides best of both worlds. Thus, it provides smooth idling at low rpm and maximum power at high rpm.

Furthermore, the newer generation VVT design implements ‘Continuous Variable Valve Timing’ or CVVT system. Besides, the CVVT varies the valve timing continuously (or infinitely) which is digitally controlled by the engine ECU. Additionally, it optimizes the valve timing for all engine speeds and conditions. Although there are different mechanisms to achieve the variation, this is mainly accomplished by using a ‘variable-timing camshaft’ and solenoid valves.

Apart from this, the CVVT uses the flexible hydraulic connection between the camshaft and its sprocket. It is operated by engine oil pressure and a solenoid-operated oil control valve which is controlled by the engine’s ECU. Furthermore, it moves the camshaft ahead and advances the timing of the opening of the Inlet valves. Some more advanced design use ‘Dual’ systems which is ‘Dual VVTi’ – one each for varying the inlet & exhaust valve timings independently.

What is VVL / VVEL / VVTL?

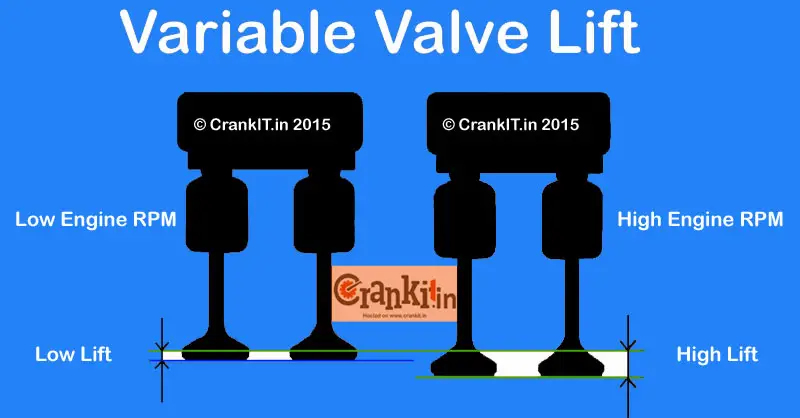

The term VVL stands for ‘Variable Valve Lift’ while VVEL stands for ‘Variable Valve Event and Lift’. The term VVTL stands for ‘Variable Valve Timing and Lift’ which is an advanced supporting system to alter the ‘lift’ of the valves. Nowadays, the ‘VVL’ system is being increasingly used in combination with ‘Variable Valve Timing’ (VVT) systems to improve the performance.

Additionally, this design also alters the lift (or travel) of the inlet valves along with valve timing depending upon the engine’s speed. Thus, it facilitates ‘low-lift‘ of inlet valves during idling or slow speeds and ‘high-lift‘ at high speeds. Also, it provides precise control of the valves while opening/closing. Additionally, to conform to stricter emissions norms, manufacturers have developed many other supportive systems. These are electro-mechanical or electro-hydraulic valve-lifters and cam-less valves systems etc.

Besides, different manufacturers use custom acronyms for their VVT systems which are as follows:

|

Acronyms |

|||

| SL. | Acronym |

Full Form |

Company |

| 1 | CVVT |

Continuous Variable Valve Timing |

Renault |

| 2 | CVVT |

Continuous Variable Valve Timing |

Volvo |

| 3 | VCT |

Variable Cam Timing |

Ford |

| 4 | VVT |

Variable Valve Timing |

Suzuki |

| 5 | VVT |

Variable Valve Timing |

Volkswagen |

| 6 | DCVCP |

Dual Continuous Variable Cam Phasing |

GM |

| 7 | VVTi |

Variable Valve Timing (intelligent) |

Toyota |

| 8 | VTVT |

Variable Timing and Valve Train |

Hyundai |

| 9 | N-VCT |

Nissan-Variable Cam Timing |

Nissan |

| 10 | S-VT |

Sequential Valve Timing |

Mazda |

| 11 | MIVEC |

Mitsubishi Innovative Valve timing Electronic Control |

Mitsubishi |

| 12 | i-VTEC |

Intelligent – Variable Valve Timing and Lift Electronic Control |

Honda, Acura |

| 13 | Camtronic |

— |

Mercedes Benz |

| 14 | VANOS |

Variable Nockenwellensteuerung |

BMW |

| 15 | Valvelift |

— |

Audi |

| 16 | VarioCam |

— |

Porshe |

Furthermore, watch the Honda i-vtec animation here:

Read more: What is Engine Valve Timing?>>