What is Dual Clutch Transmission?

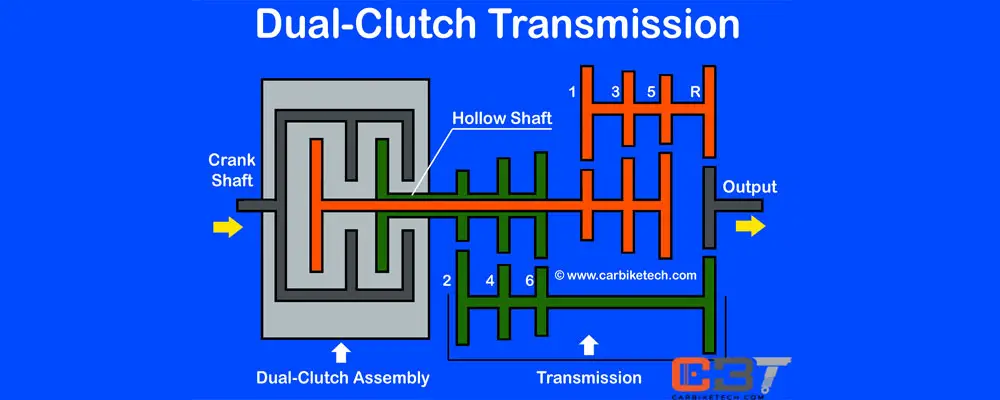

As per the terminology, the DCT stands for Dual Clutch Transmission which is a type of automatic transmission. It consists of two clutches (dual), instead of one, which operate independently of each other. Just like any other automatic transmission system, it also doesn’t have a clutch pedal. The electronic & hydraulic sensors completely control the DCT operation in a vehicle.

One of the clutches exclusively controls the odd gears i.e. 1st, 3rd, 5th & reverse while the other clutch operates the even gears i.e. 2nd, 4th & 6th gear. This facilitates the changing of gears without any interruption while the torque flows from the engine to the output shaft. The Dual Clutch Transmission uses wet-plate clutches instead of the Torque converter used in the fully-automatic transmission. It uses the lubricating fluid to reduce the friction and also to apply the pressure to the plates. Besides, the DCT uses the hydraulic pressure to drive gears.

How Dual Clutch Transmission Works?

The Dual Clutch Transmission is an updated form of the Automated Manual Transmission (AMT). This design uses two internal shafts; each connected to the input shaft thru’ an electronically controlled clutch. They are synchronized in such a way that the DCT delivers an uninterrupted flow of torque to the driven wheels while changing gears. A dual clutch transmission improves the refinement compared to the conventional manual-shift clutch as well as the pick-up of the vehicle.

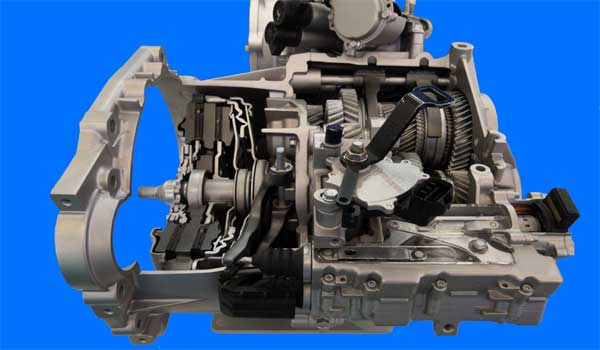

A Dual Clutch Transmission (DCT) is a type of automatic transmission. However, it is not a conventional automatic transmission. The Dual Clutch Transmission consists of two assemblies. Of which, one is the Dual-clutch module and the other is the transmission assembly with two input shafts. It also provides overlapping of the clutch engagement and a gear pre-selection system. The gear pre-selection system completes the synchronization of the next gear even before the actual gear shifting procedure starts. Thus, the DCT delivers a superior gear shifting feel while driving.

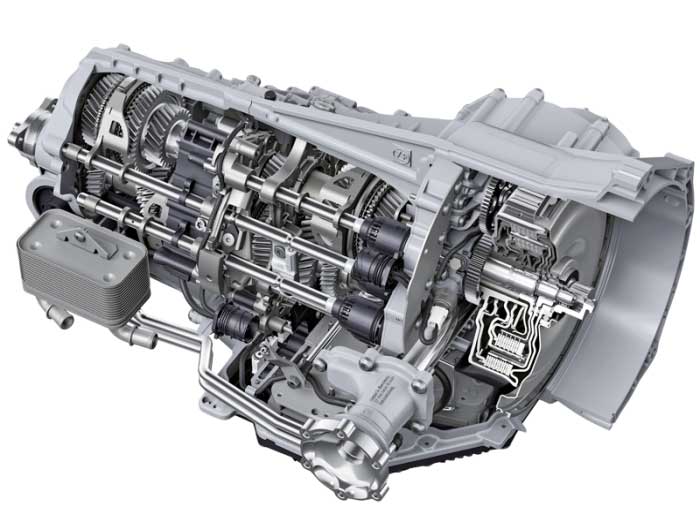

However, the DCT system uses electronic sensors, a control unit, and actuators to carry out the task of shifting gears on the driver’s command. In DCT design, an electronic mechanism/control unit actuates the clutch. The clutch itself can synchronize the timing and torque needed for the quick and smooth gear-shifts. The Dual Clutch transmission also actuates the clutch overlapping mechanism of both the clutches. Thus, during the gear shifting, the DCT transfers the torque from the engine to the driving wheels without any interruption. This eliminates any jerks or shocks while shifting the gears.

Advantages of Dual Clutch Transmission:

So, this eliminates the need for a clutch pedal in the Dual-clutch system which the driver needs to press before shifting the gears. Thus, it eliminates one more action on the driver’s part while driving. The European automobile manufacturers designed the Dual Clutch Transmission system to provide fatigue-free driving experience. The DCT is particularly useful especially in the urban cities where the stop-and-go traffic frequently causes the driver discomfort and fatigue.

Therefore, it provides a quick gear-shifting without compromising on the fuel efficiency and riding comfort. Besides, the dual-clutch module precisely calculates and accurately controls the slippage of the twin-clutches. As a result, the DCT offers a fast and smooth gear shifting. The performance of the DCT while shifting the gears largely depends upon the design and precision of the clutch engagement controller. A flawless clutch engagement controller provides faster clutch-to-clutch shifting and smooth gear-shifting without any noticeable change while transferring the torque.

Watch the Dual Clutch Transmission in action:

For more information on Dual clutch systems, please click on the following links:

Many leading DCT manufacturers such as BorgWarner, Eaton, Fiat, and ZF offer the Dual-Clutch Transmission as OEM fitment on many vehicles.