Nissan e-POWER internal combustion engine

The Nissan motor corporation is also uniquely improving its electrification of vehicles. Instead of shifting directly to mainstream electric, they are moving towards hybrid technology. But the twist is they are using IC engines only to charge the batteries instead of driving the vehicle. So, the recent invention is the e-POWER IC engine with 50% thermal efficiency.

We know that internal combustion engines are terrible in thermal management. As a result, traditional IC engines are highly inefficient. They waste most of the energy they create in Heat. So, in the case of e-POWER, Nisan shifts its focus to IC engines for charging EV batteries. Hence, they can seamlessly focus on thermal efficiency, and they achieved remarkable 50% thermal efficiency in IC engines.

Improving engine thermal efficiency has been the biggest hurdle auto manufacturers face for a long time. It took almost thirty years to improve the thermal efficiency of traditional IC engines from 30-40%. Nissan takes it further to 50% with the sole aim of electricity generation. Nissan achieves it with lean combustion technology, unique STARC 3 concept, and waste heat recovery technology.

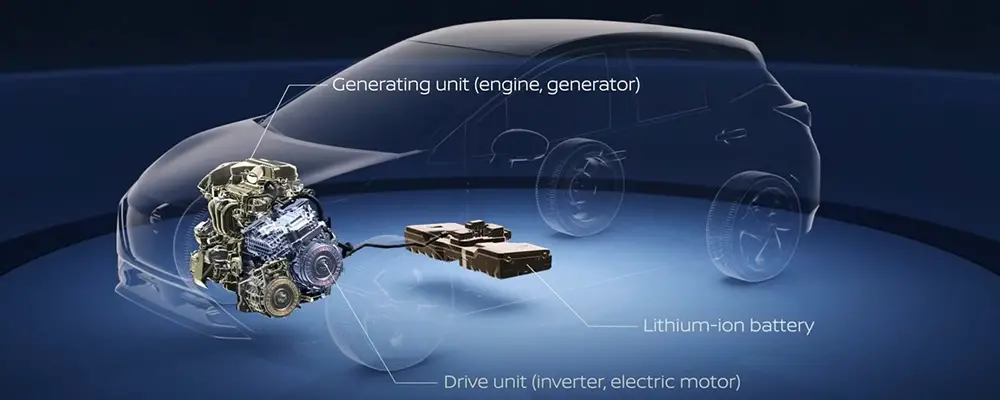

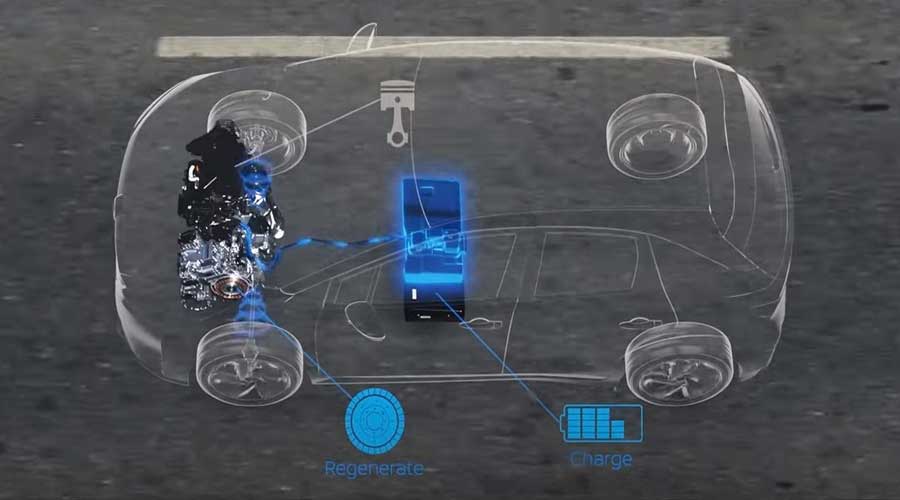

e-POWER IC engine system mechanism

The new engine has only the aim of charging the vehicle battery. Hence, the engine can operate in the most efficient range. Furthermore, Nissan is also continually developing its battery technology to achieve fixed-point driving. So, the most efficient driving is possible, achieving more fuel economy.

The engines use a new STARC concept. STARC means Strong Tumble & Appropriately stretched Robust ignition Channel. This concept optimizes the piston shape, combustion chamber, and intake manifold, keeping the fixed point operating range in mind.

The ultimate goal is to charge the batteries using the e-POWER IC engine. In addition, a stable and extended spark plug discharge channel maintains strong tumble flow in the center of the cylinder.

As a result, you can achieve stable combustion under highly diluted conditions, comparable to a High exhaust gas recirculation and lean combustion. Lean combustion involves combustion with an air-fuel mixture ratio that has more air than the theoretical air-fuel ratio.

e-POWER IC engine with 50% thermal efficiency

Manufacturers achieve basic thermal efficiency in traditional IC engines by lengthening the stroke and reducing friction. However, the Nissan e-POWER IC engine restricts the engine operating range, high EGR(Exhaust Gas Recirculation) combustion, STARC further enhances, and the use of a Turbocharger further enhances NET thermal efficiency to 43%. In addition, as battery technology improves, the engine will achieve 50% thermal efficiency in recent future.

In conclusion, an e-POWER IC engine with 50% thermal efficiency will surely increase fuel efficiency, drastically improving range and fuel economy.

Image Courtesy: Nissan