What Are The Types Of Pistons In Engines?

The piston is a fundamental part of the internal combustion engines. It has a reciprocating motion and converts heat energy into mechanical power. It travels up and down inside a cylinder when the engine produces power. The purpose of the piston is to stand the expansion of gases and send it to the crankshaft. It transfers the force of the explosion to the crankshaft and, in turn, rotates it. The piston comes with rings that seal it and the cylinder wall. It is quite complex from the design point of view.

An engine’s efficiency and economy primarily depend upon the smooth working of the piston. It should operate in the cylinder with minimum friction and be able to withstand high explosive forces in the cylinder. Besides, it should also resist the very high temperature of over 2000⁰C during operation. It should be as strong as possible while its weight should be as low as possible.

Functions Of Piston:

- To receive the thrust from the explosion and transmit the force to the crankshaft through the connecting rod.

- Also, to act as a seal so that the high combustion pressure does not escape to the crankcase.

- To serve as a guide and a bearing for the connecting rod’s small end.

It must also have the following necessary qualities:

- Rigidity to withstand high pressure.

- Lighter in weight to keep its inertia forces to the minimum and enable higher engine speeds.

- Silence in operation both during warming up and normal running.

- Its design should prevent it from seizures.

- Its material must have good thermal conductivity for efficient heat transfer. Thus, it reduces the risk of detonation and allows a higher compression ratio.

- Its material should also have low expansion qualities.

- Offer resistance to corrosion due to combustion.

- It should be of the shortest possible length so as to reduce the overall engine size.

- It must have a long service life.

Design:

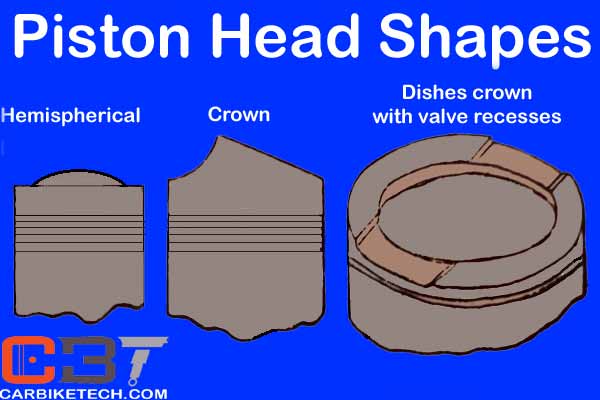

The design of the piston varies from engine to engine. It largely depends upon the design of the cylinder head. The top of the piston is called the head or crown. Generally, low-cost, low-performance engines have a flat-head-piston. However, in some cases, when it comes very close to the valves, the engineers provide a valve relief in the crown. Pistons in some high-performance engines have a raised dome that increases compression ratio and controls combustion.

Some engines use especially dished pistons to create the desired shape of the combustion chamber and the cylinder head. In case the crown contains a part of the combustion chamber, you can control the compression ratio more accurately. However, this design has a disadvantage. In this design, a large amount of heat passes through the piston and the rings.

Piston Lands:

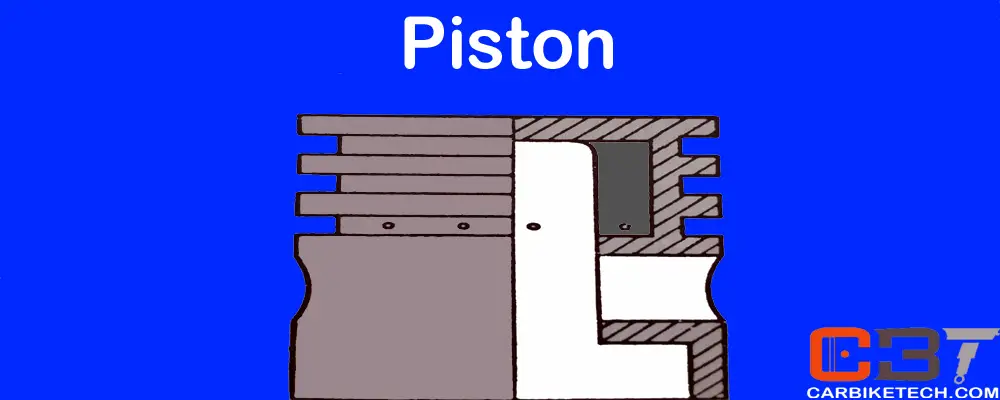

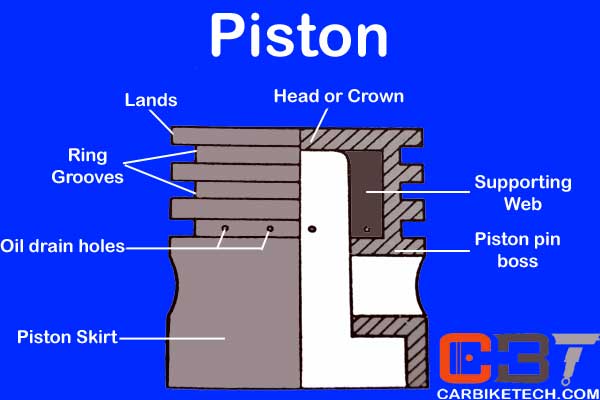

The top of the piston has grooves cut on its circumference to fit the piston rings. You know the bands between the grooves as ‘lands.’ The role of the lands is to support the rings against gas pressure. The lands also guide the rings, so they rotate freely in a circular direction. The supporting webs transmit the explosion force directly from the crown to the piston-pin bosses. Thus, it relieves the large loads from the ring grooves.

Skirt:

The part below the piston rings is the ‘skirt.’ Its role is to form a guide and absorb the side thrust created by the gas pressure. The skirt has bosses on the inside to support the pin. It fits quite close in the cylinder; however, it is separated from the cylinder walls by lubricating oil. The combustion forces are transmitted from the crown to the connecting rod through webs inside the piston. Besides, the bosses act as a bearing surface for the rocking motion of the connecting rod. The thick-section webs transfer heat from the crown to the gudgeon-pin bosses & skirt.

Earlier engines used cast iron for its wear-resistant qualities. However, modern engines use aluminum-alloy, containing silicon for pistons to reduce weight. It is three times lighter than aluminum, so it has lower inertia. In addition, aluminium-alloy possesses high thermal conductivity, which allows it to run cooler.

Piston Clearance:

Usually, the piston is slightly smaller in diameter than the cylinder bore. Therefore, the space between it and the cylinder wall is called piston-clearance. This clearance is necessary for the following reasons.

- It provides a space for a film of lubricant to reduce friction between the piston and cylinder wall.

- It prevents seizures. Piston and cylinder block expand due to very high temperatures. However, the system cools the cylinder better than the piston. Hence, there must be sufficient clearance between them for it to expand.

- Without sufficient clearance, it will be impossible for the piston to operate in the cylinder, reducing its efficiency.

The amount of clearance depends upon the cylinder bore’s size and the piston’s material. But, usually, it is 0.025mm to 0.100mm. In operation, a film of lubricating oil fills up the clearance space. Therefore, technicians must maintain proper clearance between piston and cylinder while overhauling the engine.

Effects of Clearance:

If the clearance is too small, it will increase the friction, resulting in a loss of power. If the clearance is too much, it will result in ‘piston slapping.’ It means sudden shaking of the piston when it goes downward in the power stroke, causing a distinct noise. As the engine warms up, this clearance reduces, and the noise usually disappears. Manufacturers use special alloys and different designs to reduce the slap.

Mahle, Diamond, CP Carrillo, Ross, and Arias are some of the manufacturers of pistons in the world.

Watch Mahle Piston In Action:

Read More: Cylinder Block Design>>