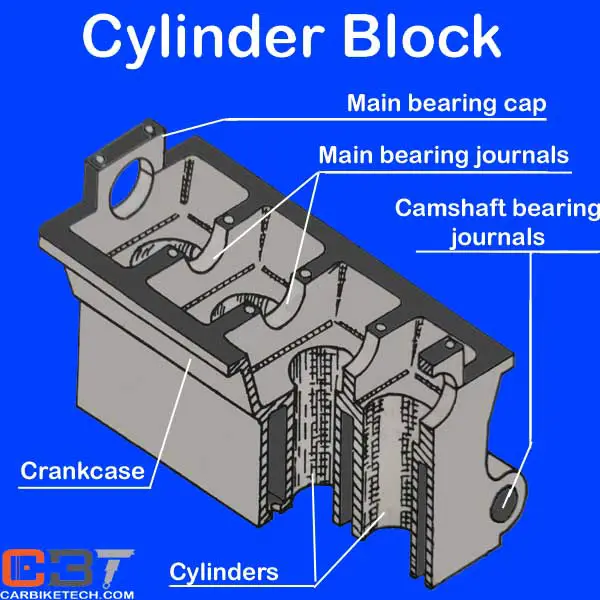

Cylinder Block: Construction, Type, and Composition

An automotive engine mainly consists of three stationary parts which are cylinder head, cylinder block, and crankcase. They provide support and serve as an enclosed unit for other moving parts. Modern engines consist of cylinder block and crankcase as a single unit which provides rigidity. The crankcase has ribs cast into it which gives added strength and also supports main and camshaft bearings. In some large engines, the block may also employ a separate crankcase for the crankshaft.

The cylinder block is one of the most important designs in the engine. Just as head, the cylinder block is also designed to achieve certain performance parameters. It must sustain very high pressures and temperatures running above 600 degrees Celsius. So, manufacturers use precision methods to design and manufacture cylinder blocks. They employ precision machining to give mirror finish to cylinder surfaces. This includes accurate grinding and honing processes.

The cylinder block mainly consists of three parts:

- The cylinders in which the pistons go up & down.

- The ports or openings for valves.

- The passages for the smooth flow of cooling water and lubricating oil.

Materials:

Usually, manufacturers use grey cast iron for cylinder blocks while sometimes adding nickel and chromium. Nowadays, they also use aluminum to reduce weight and improve performance. However, the aluminum blocks use cast-iron or steel sleeves on cylinders. Most engines prefer cast-iron for cylinder walls as it has lower wearing qualities. Some small engines use chromium for plating cylinder walls to reduce wear & increase service life.

Manufacturers are conducting tests on silicon-aluminum alloys for their use in cylinder blocks. These alloys have a low coefficient of thermal expansion and high wear resistance. Besides, aluminum alloy blocks maintain more uniformity of temperature because of their thermal conductivity. Often, manufacturers use the block, head, and crankcase made of aluminum alloy. Grey cast-iron for the block is the same that is used for the head. However, aluminum alloys are usually quite different. Cast iron is still used for heavy applications such as commercial engines, rail- engines and marine engines.

Composition:

The composition of a cast-iron cylinder block is as below:

Iron 95%

Carbon 2.2%

Silicon 1.2%

Manganese 0.63%

Sulfur 0.12%

Phosphorus 0.85%

A typical aluminum-alloy for cylinder block & piston is as below:

Aluminum 91%

Tin 2%

Copper 7%

Construction:

Furthermore, the head is attached to the top surface of the cylinder block with studs/bolts. A gasket is used between the head and the block to provide a seal to prevent leakage of gases. Besides, the block also has ports, oil passages and water jackets carved inside it to provide lubrication and cooling. However, some cylinder blocks also house camshaft & have provisions to mount the related parts.

Moreover, the L-head engine blocks also contain openings for the valves & valve ports. The bottom of the block supports the crankshaft and also the oil pan. In most engines, the block also supports the camshaft through bushings that fit into machined holes. In some engines, the intake and exhaust manifolds are attached to the sides of the block. Other parts fitted to the block include the water pump, timing gear (both at the front) and flywheel, clutch housing (both at rear). They also include ignition, distributor, and fuel pump.

Furthermore, water-cooled engines have passages carved into the block. The circulating water maintains the engine optimum temperature and avoids excessive expansion and distortion of moving parts. Thus, it prevents the seizure of the relative moving parts.

Cummins, Detroit, Volvo, and MAN are some of the major engine manufacturers in the world.

Read more – What is Compression Ratio?>>