Ignition System in Petrol Engines:

An electrical system that facilitates delivering an extremely strong electric pulse to each spark-plug is called the ignition system. It supplies the high voltage current all the way from the ignition coil to the spark plug.

Manufacturers employ the ignition systems specifically in the spark-ignition (SI) engines. Its because they use the spark-plug to ignite the air-fuel mixture. It works on the petrol engine for igniting the air-fuel mixture. However, a diesel engine DOES NOT need an ignition coil.

Types of Ignition Systems:

Manufacturers employ different types of ignition systems in vehicles. The first type comes with the ‘contact-breaker’ mechanism that triggers the spark. Earlier generation vehicles used this type of ignition system.

The second type is ‘breaker-less’ or ‘contactless’ ignition. In this, the manufacturers use an optical pickup or electronic transistor as a switching device. This is the most common type of ignition system that you can find in modern cars.

The third type is the capacitor discharge ignition. In this technology, the capacitor all of a sudden releases the energy stored in it through a coil. It also has the ability to produce the spark in low conditions where the conventional ignition may not work. CDI also helps in conforming to the emission control regulations. Due to the several benefits it offers, it has become a standard feature in modern cars and motorcycles.

Components of the Ignition System:

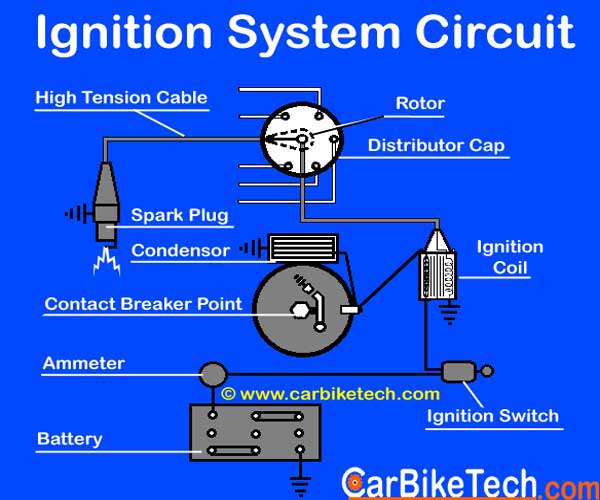

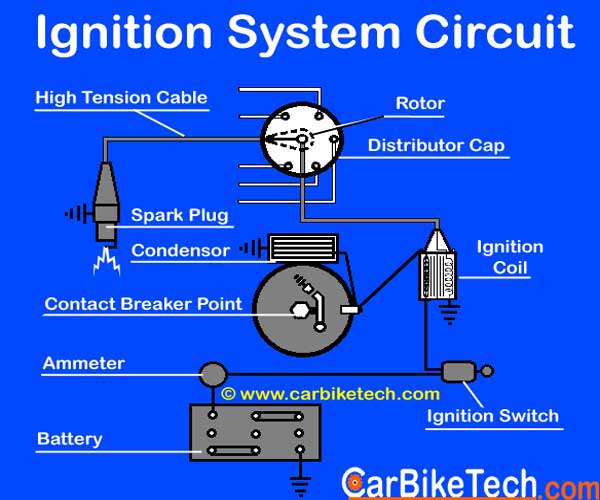

The conventional Ignition System consists of the following parts.

- Ignition Switch

- Ignition Coil

- Distributor

- High Tension Cables

- Spark Plugs

Working:

The conventional ignition system consists of two sets of circuits/windings – primary and secondary. The battery supplies 12 volts current to the ignition coil thru’ the contact breaker points. It charges the primary windings and also magnetizes the core of the coil. However, the secondary winding is NOT electrically connected to the primary winding. Its one end is grounded and other end passes thru’ a heavily insulated cable into the distributor cap. When you turn on the ignition switch, the current passes thru’ the primary winding to the ground (earth) thru’ the contact points.

The rotating cam is attached to the distributor’s drive-shaft that is driven by the engine. When the drive-shaft rotates, it turns the cam. When the cam pushes the movable breaker arm, it lifts from its seat. Thus, it breaks the contact. As soon as the contacts break, it induces the secondary winding with a high voltage current of around 20,000-25,000 volts.

This high voltage current then passes thru’ the high tension cable and reaches the top of the distributor cap. The distributor cap sits on the distributor’s drive shaft and rotates in the direction of the drive-shaft. While doing so, it aligns with the high tension cables corresponding to each spark-plug. The engineers design the alignment of the drive-shaft with the engine in such a way that the lobes of the cam open the contact points at the end of the compression stroke of each cylinder. Then, the high voltage current passes on to the respective spark plug that creates the spark.

Electronic Ignition System:

Electronic Ignition uses electronic controls that replace the electromechanical components used in earlier generation vehicles. It creates the electric impulses and supplies them to the spark plugs to ignite the air-fuel mixture. Electronic Ignition DOES NOT use the electromechanical parts as the same as the older system. However, it uses an electronic switching device which sends electrical impulses to the spark plugs and thereby ignites the fuel. Electronic ignition also has the ability to maintain correct ignition timing. And, at the same time, it gives a constant output of high current.

Advantages:

The electronic ignition systems are more efficient. They also support higher engine horsepower levels than the older mechanically controlled systems. The most important advantage of this system is that it is circuit-based rather than mechanically controlled. It controls the flow of electric current accurately and reliably by using sensors, electrical switches, and transistors. These systems are also very durable.

Thus, the Electronic Ignition system is better than the mechanically rotating distributor head in all respects. Due to its high level of precision, it helps in the complete combustion of the air-fuel mixture in the engine. Thus, it results in better fuel economy as well as lower emission. It also supports many systems that use electronic control. Denso is one of the leading manufacturers of the ignition systems.

Watch the Ignition System in action here:

Read On: What is Ignition Timing?>>