What is Ignition Timing?

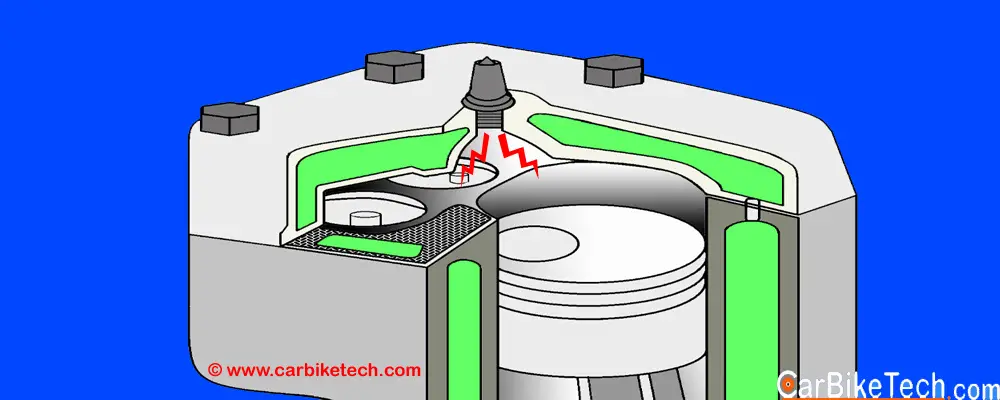

Ignition Timing is a process to deliver spark at the correct time. It sets the pointer with respect to the piston’s position and the crankshaft’s velocity. Thus, it provides the spark at the most accurate timing to burn the air-fuel mixture. The Ignition System provides a spark at the end of the compression stroke in the combustion chamber at an appropriate time. Hence, it is known as Ignition Timing. You should set the timing according to the engine design and as specified by the manufacturers. If the spark occurs too early or too late in the engine cycle, it results in excessive vibrations. It may also cause damage to the engine.

Ignition timing also affects several variables. They include the engine power, torque, fuel economy, and also the engine’s life to some extent. Modern engines’ control unit uses a computer to precisely control the ignition timing. The earlier generation cars required the driver to control or adjust the timing as per the driving conditions. However, these days, those actions have been automated in modern car engines. Therefore, whenever you carry out any significant changes to the engine, you may also need to implement the necessary changes in the ignition timing.

Timing Marks:

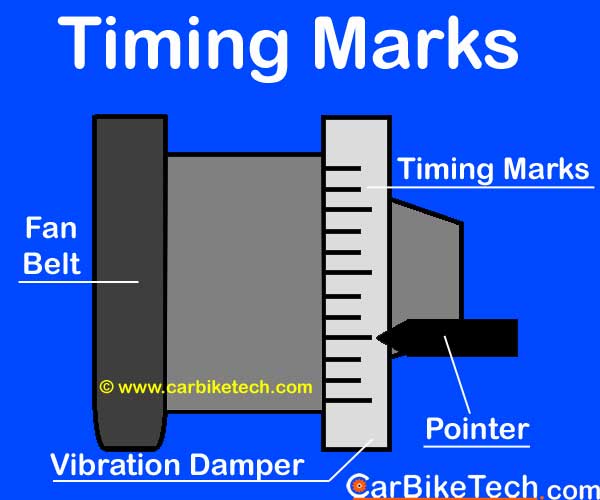

The manufacturers provide the ‘Timing Marks’ as the indicators for setting up the ignition timing for the engine’s ignition system. The manufacturers carve out/punch these marks on the crankshaft number of degrees before the Top Dead Centre (TDC). The engine-makers usually punch the timing marks on the vibration damper. These could be at the front or on the flywheel at the rear of the engine.

At times, the crankshaft pulley locates these marks. Or, they could be on the largest radius that rotates at the speed of the crankshaft. Timing marks indicate the number of degrees before the Top Dead Centre (TDC). The older engines used the timing light for setting up the ignition timing.

You can set the ignition timing at the correct firing point while the engine rotates. However, it has to be precisely a few degrees before the Top Dead Centre (TDC), which could advance with increasing engine speed. You can adjust the timing by loosening and/or rotating the distributor on its seat. Modern engines have a crank angle sensor that directly connects to the engine management system. The crankshaft’s timing marks must also match that of the camshaft to achieve the correct valve timing.

Automatic Ignition Timing Advance:

A certain delay, called the ‘Ignition delay,’ to start the combustion after it fires the spark. The spark must occur before the moment at which the cylinder reaches the maximum pressure. Ignition Advance is the difference between this moment and the occurrence of the spark.

The timing advance occurs when the ignition occurs earlier in the compression stroke, i.e., before the Top Dead Centre (TDC). However, if the spark advances too much, the combustion will complete even before the piston reaches the TDC. Then, the crankshaft and connecting rod would have to force the piston to move upwards against the compression stroke pressure. In such a case, this force might not be sufficient to overcome the compression pressure.

As a result, the engine could stop or stall. An advanced spark may also cause the fuel to explode or detonate midway to produce an audible knock. However, the timing advance is necessary when the engine operates at full speed. Thus, it allows sufficient time for burning the air-fuel mixture. The engineers need to control the ignition timing advance accurately. So, they provide different systems such as manual, centrifugal, vacuum advance, and complete vacuum control mechanisms.

The ‘Timing Advance’ depends on the following factors:

- Nature of fuel

- Engine speed

- Load on the engine

- Engine temperature

Ignition Timing Retard:

On the other hand, the timing retards when the spark occurs late or at the end of the compression stroke. There is a component that retards the timing called the timing retard. The manufacturers mostly employ the timing retard functionality to supplement the regular braking in vehicles. The braking friction causes the brakes to fade if used extensively for an extended period. It can be dangerous too if the braking performance drops below the desired value for stopping the vehicle.

So, the engine retard function helps to slow down the engine performance. Thus, it delivers the spark later in the engine cycle. Some engines also retard the valve timing to compensate for the ignition timing retard. The retarding of the engine lowers the engine speed and causes a loss of power. Also, it can cause engine knocking, which can harm the engine.

The electrical retarding mechanism uses electromagnetic induction to provide the force of retardation. The manufacturers place the electric retardation unit onto the transmission or the axle, consisting of the rotor. However, there is no contact between the rotor and the stator surface.

Watch Ignition Timing in action here:

Read more: What is Valve Timing?>>