Spark Plug Construction & Working:

A spark plug is very important in a petrol engine when it comes to igniting the charge in the combustion chamber. As the name suggests, the spark plug creates a spark that burns the air-fuel mixture. It consists of a center electrode, a ground electrode, an insulator, and a shell/body. Ignition coil provides the electrode with a very high voltage of around 20,000 volts which produces a spark to burn the air-fuel mixture.

Construction:

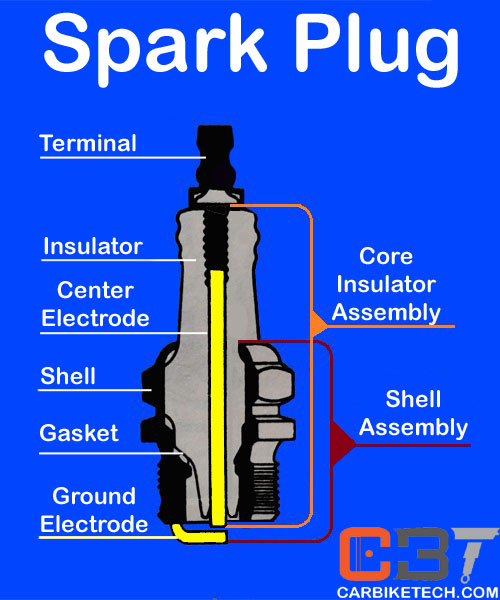

A typical spark plug consists of a steel-shell assembly which serves as a housing for the core-insulating assembly. It has the ground electrode fixed to its lower threaded portion. The upper part is hexagonal in shape; just like a nut. It acts as a surface for the wrench to screw and unscrew the plug from the cylinder head. The core assembly consists of an insulator that can withstand high voltages, pressures, and temperatures. The center electrode is fastened into the insulator. The upper end of the center electrode is connected to the spark-plug wire terminal while its lower end projects beyond the insulator and forms a gap with the ground electrode. A gasket between the insulator & shell prevents the combustion gases to escape under high pressures & temperatures.

Spark Plug Material:

The material of the spark plug is of corrosion-resistant type. Earlier generation plugs used nickel. Nowadays, manufacturers use platinum and iridium-alloy on the central electrode. Iridium is one of the hardest metals in the world.

Iridium starts to melt at 2450°C. It is also very resistant to spark erosion. Iridium can reduce voltage demands by 24%, leading to longer life of spark plug. On average, Iridium spark plugs offer double the service life compared to standard nickel plugs.

Some of the spark plugs have a platinum plate on its central electrode. It provides a more constant output even under difficult conditions throughout its entire service life. It emits very little spark voltage, discharges the ignition coil quickly, and carries out optimal combustion.

Working:

Furthermore, the primary ignition circuit induces a high voltage current into the center electrode. This high voltage current travels down the center electrode; jumps the gap to the ground electrode and completes the secondary circuit. The sealing gasket provides the sealing between the plug shell and cylinder head and helps in the conduction of heat. Thus, the high voltage current, in order to be grounded, jumps the gap between the center & ground electrodes. This process produces a strong spark to burn the air-fuel mixture.

Spark Plug Gap:

The electrical resistance of the sparkplug depends on many factors. They include the nature and pressure of the air-fuel mixture, and also the distance between the electrodes. This distance is known as the spark plug gap. This gap needs to be adjusted as per the manufacturer’s specifications by bending the ground electrode. The gap can be checked by using a feeler gauge. Too much or too small gap decreases the efficiency of the ignition system. This, in turn, causes loss of engine power and efficiency.

Maintenance:

Over time, foreign materials such as carbon or excess oil sludge accumulate between the electrodes or inside of the insulator. They facilitate some of the high voltage currents to by-pass the spark plug gap. This reduces the intensity of the spark; results in the reduction of combustion efficiency and loss of engine power. When these current leaks become excessive, the spark plug will not ignite the air-fuel mixture properly.

So, that particular cylinder will not produce the desired power and stop working. Foreign materials lodging between the electrodes can also short-circuit the plug. So, you need to periodically clean the spark plugs and adjust the gap. Modern Plugs like Bosch OE-Fine Wire Platinum come with the factory pre-set gap for popular vehicle applications. Hence, gaps should never be adjusted on these plugs by the installer.

Common Problems:

Furthermore, the fouling of spark plugs is nothing but accumulating different deposits such as carbon on the electrodes. When it is functioning properly in normal conditions, the electrode of the plug attracts some particles from the ignition gas. They obviously block the gap between the two electrodes. Some of the particles that are coated on the spark plug end turn into the shiny finished coating. It then becomes an electrical conductor that causes the spark to by-pass/escape the gap. This leads to misfiring in the engine which is a very common problem.

Other Issues:

Moreover, engines that use the contact breaker ignition technology often have a plug-fouling problem. However, the use of the electronic ignition system eliminated this problem significantly. The accumulation of the particles occurs because of the passing electrical charge on the positive electrode. Thus, taking care of the spark plug by timely servicing can help to lessen this problem and also improve the performance of the engine.

Bosch, Denso, Champion, Autolite, and NGK are some of the leading manufacturers of spark plugs in the world.

Title Image – Courtesy (Bosch)

Read more: How does a fuel injector work?>>