What is the worm and sector Steering Mechanism?

Manufacturers employed worm and sector steering on earlier generation cars. This mechanism transmits the motion from the steering gear tube to the Pitman arm. It was

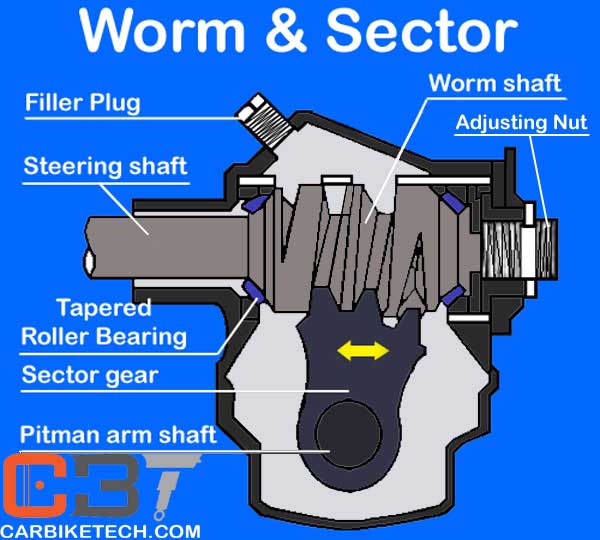

This steering gear consists of case-hardened steel worm and sector; both supported by bearings. Its casting is made from malleable iron or light alloy. The worm connects to the steering shaft while the sector forms a part of the rocker shaft.

Design:

The steering gear mechanism has the following three main adjustments:

- Shim adjustment for end float of inner column.

- Shim of screw adjustment for end float or rocker shaft.

- Closer movement of gears for backlash between gears.

This steering gear appear more like a bolt and nut. However, the sector gear looks more like a gear instead of a nut. The sector has external teeth that are machined in an arc or curve. They actually appear to be a section of the full gear. As the driver turns the steering wheel, the worm rotates the sector and Pitman arm shaft. The sector gear rotates through an arc instead of a full circle. This is because it stops at each end by the steering gear housing.

Worm and Sector Steering Operation:

In this type of steering mechanism, the steering shaft has a worm gear attached to it at its end. It meshes directly with a sector gear. It is called ‘sector’ gear because it’s only a section of the full gear. When you turn the steering wheel, the steering shaft turns the worm gear. The sector gear rotates around its axis as its teeth move along the worm gear and

In worm and sector design, the bearings support the worm at both ends. Besides, the manufacturers provide some mechanism for adjusting the bearings to control the end play. The Pitman arm shaft fits into the steering gear housing supported by bushings. However, sometimes the manufacturers also use roller bearings. They also provide a screw for backlash adjustment to move the sector closer or away from the worm gear. This controls the backlash between the sector and worm threads or teeth.

Maintenance:

Generally, in this steering, the manufacturers make the gear with a larger backlash in the lock positions. This is because the maximum wear occurs in the straight-ahead position of the gear. When the box is adjusted to compensate for the wear, it reduces the risk of seizure at the full lock position. Furthermore, you should reduce the end float and backlash. However, the driver should also avoid the tight turns, if any. For lubrication of the steering gear, the manufacturers fill the box to the level of the with normal gear oil.

For more information, please click here.

Watch worm and sector steering mechanism in action:

Read more: How Rack & Pinion Steering Works?>>