What Is Cylinder Deactivation?

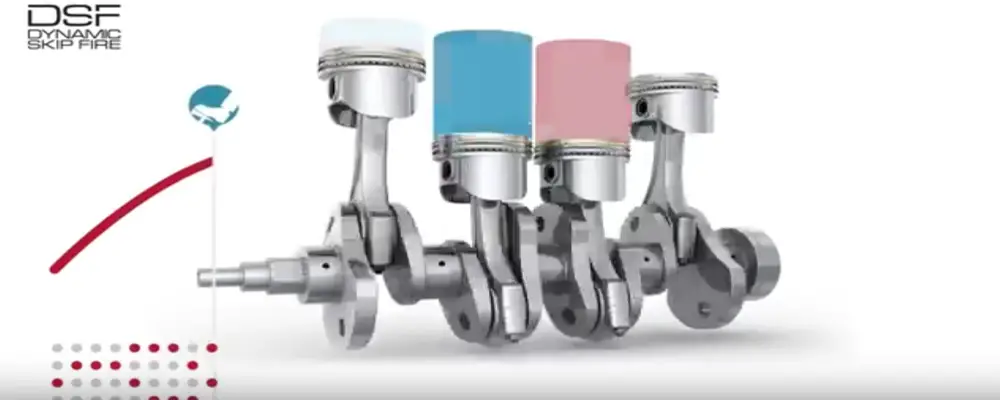

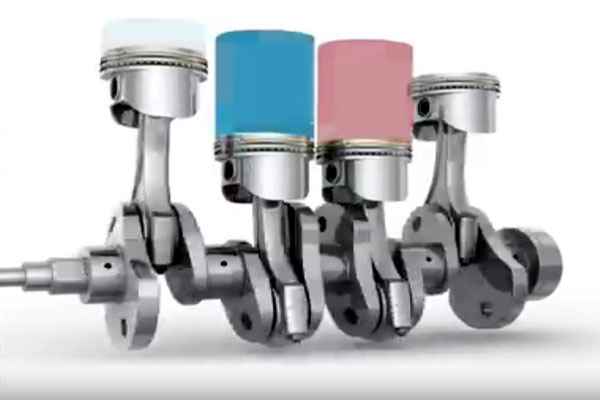

In conventional cylinder deactivation technology, the system closes its intake valves, which draw in air and exhaust valves, releasing expanded gases. It also stops injecting fuel into the cylinder. The piston still moves up and down because it’s connected to the rotating crankshaft. However, this system deactivates a fixed number of cylinders. Dynamic Skip Fire is a more advanced modern technology for cylinder deactivation.

What is DSF Technology?

DSF stands for Dynamic Skip Fire. It is a trademarked technology by Tula Tech. It is a modern development of cylinder deactivation technology. Manufacturers use it for engines with proven cylinder deactivation hardware. According to Tula, DSF boosts fuel efficiency between 7-15% through optimized combustion and reduced engine pumping losses.

Current cylinder deactivation tactics shut off a fixed number of cylinders. However, DSF makes dynamic firing decisions every 90 degrees of crank angle on a V8 (or 180 degrees on a 4-cylinder engine) based on how much torque is required. As a result, the engine dynamically fires the optimal number of cylinders. Thus, it maximizes fuel economy and maintains a smooth ride.

How does DSF Technology work?

This technology uses dynamic downsizing. DSF technology controls power output by dynamically deploying each engine cylinder event in real-time.

Transforms the engine to optimize:

Furthermore, Dynamic Skip Fire technology is highly responsive to variable engine displacement. When the driver requires more torque, the firing density increases. With less demand for torque, the firing density decreases. Firing density is the ratio of cylinders actually fired to the maximum permissible. The DSF algorithm then transforms the engine to optimal displacement for the torque required.

The energy gets wasted in Non-DSF engines as they close the throttle to limit air intake, increasing pumping losses. So instead, DSF limits the cylinder firings, reducing pumping losses and increasing efficiency.

Advantages of Dynamic Skip Fire: Fuel Efficiency

DSF software and engine control algorithms create optimum fuel efficiency by individually firing cylinders. Thus, it precisely matches the driver’s request for torque. It selects each combustion event to allow optimal efficiency. Hence, DSF reduces fuel and CO2, and NOx emissions for diesel applications. Tula’s proprietary firing decision and control algorithms also avoid noise and vibration generation. It gives drivers desired levels of refinement under all driving conditions.

Low Noise & Vibrations:

Tula has developed DSF technology algorithms to maintain a smooth ride for any amount of requested torque. In addition, its algorithms avoid generating noise and vibration (N & V) to give drivers the desired refinement levels under all driving conditions.

Watch Dynamic Skip Fire Technology In Action Here:

Read more: How Fuel Injection Technology works?>>