Wheels:

Wheels are as essential parts of a vehicle as any other part. Generally, the wheel consists of a hub, disc or spokes, rim, tire & tube. Besides all the components being perfectly in working order, the vehicle still can’t move on the road without wheels. Wheel balancing is an important aspect of the wheels for better stability of the vehicle.

Further, the wheels support the weight of the vehicle and protect it from road shocks. Besides, the rear wheels move the vehicle while the front wheels steer it. All four wheels must resist the braking stresses and withstand the side thrust.

To perform the abovementioned functions, the wheels must be:

- Strong enough to withstand the weight of the vehicle.

- Flexible to absorb the road shocks.

- Abide to grip the road surface.

- Perfectly balanced both dynamically and statically.

- Light and easily manoeuvrable.

Wheel Balancing:

Balancing the tires is nothing but the balancing of the wheels. It distributes the weight within the vehicle wheel. It has an asymmetrical mass that causes it to hop or wobble. The suspension of the vehicle can attract an unbalanced force of the tires’ speed.

Moreover, the balance of a tired wheel is essential to avoid front wheel wobble. It affects the steering and increases the rate of tire wear. You require the wheel balancing most after the accidents. It provides a spun speed, and the wheel performs in the best-balanced performance for the vehicles. Thus, there is no part of the wheel that should weigh more than any other part.

The following factors affect the wheel & tire assembly imbalance:

- Lateral run-out of the wheel.

- Radial run-out or out-of-round wheel, caused by tyre or rim being out-of-round.

- Uneven distribution of weight around the axis of rotation.

Therefore, it is critical to inspect the wheel centering before checking the wheels for balancing. Lateral run-out is usually the result of a warped rim from road shocks. However, you can correct it with the help of Arbor press. First, you must remove the tire to straighten the wheel rim. Then, turn the wheel rim on its axis and check the wheel inside flanges, retaining the tire bead and the rim well for an excess run-out.

Manufacturers provide two types of the balances such as dynamic and static. The wheel lacks the static balance of the weight for not distributing it eventually around the hub. It is the heavy side of the wheel that goes to the bottom side. The dynamic balance can consider the distribution of the masses around the panes of the rotational motions. The wheels or tires can bring together the balance statically, but it is not dynamic. It is the leading wheel that wobbles at a certain speed.

Static Balance:

You can make the static balancing of the front wheels with an electronic balancer with the wheels fitted onto the vehicle. Thus, it gives a remarkable advantage of balancing the wheels with the other rotating masses.

Carry Out Static Wheel Balancing As Follows:

- Lift the front wheels on a hydraulic jack.

- Make sure that the wheels can turn freely.

- Then, arrange the spinner with its pulley in touch with the tyre tread. Besides, the wheel should be in straight ahead position.

- Move the balancer int position to point the strobe light at the wheel.

- Position the pick-up magnet in contact with a clean flat surface on the front suspension as close to the wheel as possible.

- Trace of apply the reference mark on the wheel cap or tyre, consisting of a radial line. Use chalk or tape for this.

- Then, shift the balancer switch to position 1 and with some minutes to allow the warm up of tubes. If the pick-up magnet is in proper contact, the strobe light will flash when the top of the tyre is tapped.

- Start the wheel by hand. Snap on the switch for the spinner motor. Then, hold the spinner pulley. Then adjust the tyre tread to speed up the wheel.

While the wheel is spinning, you will experience the following conditions:

- The flashing of strobe light will make the reference mark on the wheel. It will appear to be fixed in the same position.

- Now, watch the meter of electronic balancer. The needle will move on from zero position. When the needle reaches its highest reading and starts moving back, then pull the spinner away.

- Inertia causes the wheel to keep running and the needle will rise again. When the meter needle matches its higher reading, note the position of the reference mark. Consider the reference mark as the hour hand of the clock. The “time” reference mark indicated the position to remember.

- If the meter needle remains in the green zone, the wheel is is balance. If the meter needle rides the green zone, then the wheel is out of balance.

In this case, operate as follows:

- See whether you have applied the balancing weights to the wheel. If so, remove them and repeat the process of 7 (a), (b), and (c).

- Now, move the wheel by hand to the same reference mark position or “time” recorded at 7(c).

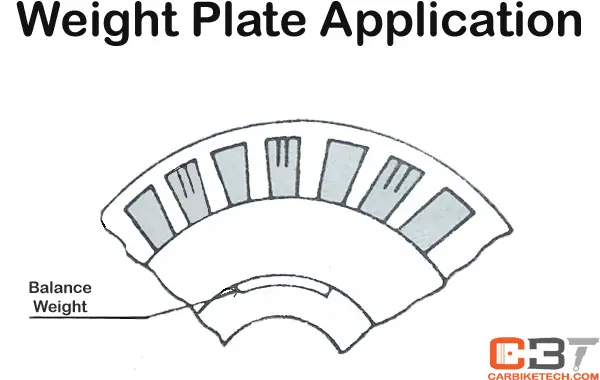

- Apply a weight corresponding to the maximum meter reading at the inner top end of the wheel. The weight should be approx.. 14gms for every division on the meter dial.

- Repeat the abovementioned inspection procedure. Then, note maximum needle reading on the meter dial & the reference mark position or “time.”

If the needle still moves beyond the green zone, proceed as follows:

- Stop the wheel.

- Move the wheel to the wheel to the same reference mark position or “time” recorded at “9.”

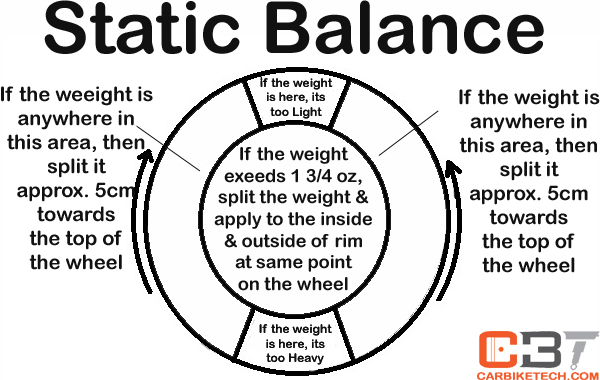

- Change or shift the weight as shown in the diagram.

- Repeat the check as directed previously. If the wheel is still out of balance, proceed with the balancing procedure till the meter needle remains in the green area.

Static Wheel Balancing of Rear Wheels:

For the static balance of rear wheels, proceed as follows:

- Place the jack under the rear axle housing. Raise the wheels high enough to slide the block under the rear wheel to be balanced.

- Position the pick-up magnet in contact with the lower axle end as close to the wheel as possible.

- Balance rear wheels proceeding as described for static balance of front wheels. Run the engine of the vehicle to spin the rear wheels.

Note: You can give the rear wheels only static balance.

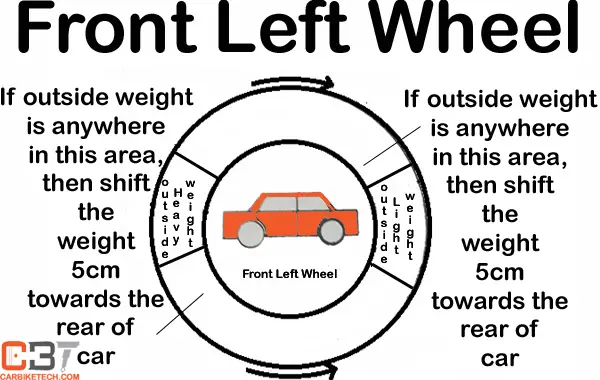

Dynamic Wheel Balancing of Front Wheels:

For dynamic balancing of front wheels, proceed as follows:

- Turn the wheels out approx.. one and half of their steering angle.

- Position the pick-up magnet in contact with the external front of the brake housing flange at the wheel rotation axis.

- Spin the wheel and record the highest meter reading as well as the corresponding position of the reference mark, following the static balance procedure.

- If the meter reading moves out of the green area on the dial, the wheel is out of balance.

In this case, proceed as follows:

- Move the wheel by hand to the same reference mark position as recorded in point no. 3.

- Then, divide the total indicated weight in half & apply.

One half at the inside front end of the wheel is in line with the horizontal wheel axis.

The other half is at the outer rear end of the wheel in the opposite position to the first half.

- Check the dynamic balance of the wheel as done for the static balance.

- If still out of balance, stop the wheel and brin the reference mark in correspondence with the position or “time” recorded in point no. 3.

Proceed as shown in the diagram.

Note: Remember that you should shift both the inner & outer weight plates to correct the balance. Set weight at opposite diametrical positions to not alter the static balance.

- Repeat the inspection as directed previously. If the wheel is still not balancing, proceed with the balance procedure till the meter needle remains in the green zone.

Furthermorem the main benefit of balancing a wheel is that it allows kneading for any brake disc, drum, or hub assembly imbalances. Unfortunately, the unbalanced wheels result in flat spots, rapid tire wear and tear, and vibrations.

The vibrations in a vehicle occur for many reasons. It can have poor wheel balanced or imperfect tires, brake pulsation, and loose driver-line and suspension components. You can occasionally use it to find the foreign material stuck to the tires for causing the vibrations. E.g., the road tar usually comes out & sticks to tires in summer. It has a small weight attached to the vehicle’s wheels for balancing them.

Modern wheel balancing machines use digital applications for accurately balancing the wheels of the vehicles.

John Beam & Hunter are some of the wheel balancing machine manufacturers in the world.