What Are Cylinder Liners?

Manufacturers fit unique sleeves or cylinder liners into the bored holes of the cylinder block to increase the engine’s service life. Thus, it also helps bring the engine size to a standard size. In addition, the steel used for the liners is about four times more resistant to wear than the cast iron used for the cylinder block. Thus, the mechanics can also use liners on old engines.

Generally, manufacturers use two types of liners – dry & wet.

Dry Liners:

Manufacturers make dry liners in two stages. Besides, they differ in their fit into the cylinder block. Therefore, manufacturers use accurately machined holes to fit them. While fitting, they don’t make a close contact between the bore & outside surface of the liners. However, it causes a local hotspot to occur. Thus, it results in piston seizure. It is due to rapid wear due to areas of reduced contact surface area.

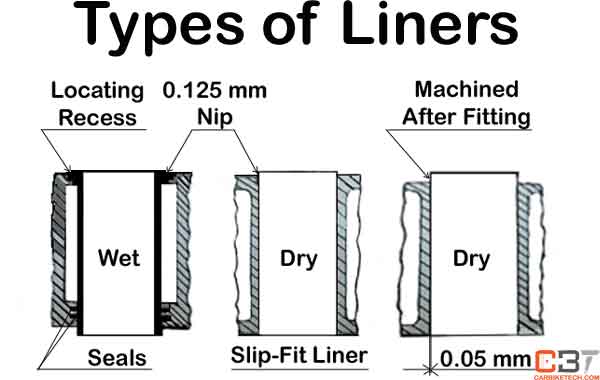

The dry liners are dominant in the working parts for reciprocating the engines. They are the space in which the pistons can travel. The dry liners are those cylinder liners that move inside the cylinder. There are different types of dry liners. Manufacturers term the dry liners “slip-fit” types, free in their bores. However, the other type can press into the existing cylinder bore itself. The dry liners have watertight joints at the bottom end. It has a seat that fits into the crankcases at the top end. It can make its way up to the cylinder head.

Slip-Fit Liners:

Manufacturers machine-finish the “slip-fit” lines both internally and externally. Besides, you can replace them when worn out without the need to remove the engine from the chassis. They protrude about 0.125 to 0.2 mm from the cylinder block when fitted. Besides, a flange and a recess hold them in position. Then again, the protruding helps to ensure that the cylinder head gasket grips evenly by the liner flange.

You also know the dry cylinder liners as “interference-fit” liners, roughly finished to fit internally. Besides, they project externally about 0.5 mm above the cylinder block. Therefore, you should well grease them externally before pressing them with a special liner press into the cylinder bore. Besides, you must thoroughly clean the cylinder block and check for its size, roundness, and parallelism. Besides, it would be best if you fit them alternatively and not in numerical sequence to avoid the possibility of distortion of the cylinder block.

Wet Liners:

Manufacturers prefer these types of cylinder liners in the construction of large engines, especially in car engines. Thus, it is because they are simple to replace when worn out. Besides, they have the advantage of more efficient cooling.

While manufacturing, the manufacturers hold them in position at the upper end of the box-type cylinder block. It has a shoulder fitting into a recess at its top end. Besides, manufacturers use rubber sealing rings, a shoulder, or a paper gasket to seal its lower end. To get a gas-tight joint, it is necessary to protrude the liner about 0.125mm above the cylinder block’s surface around its periphery.

Before fitting the liner, you must check the shoulder. Besides, you must also check counterbore seatings for truth and cleanliness. The damage to seats could occur due to the accidental movement of the liners. To prevent this from happening, you should NOT rotate the crankshaft until & unless you have clamped down the liners.

Mahle is one of the leading manufacturers of cylinder liners in the world.

Watch How They Manufacture Cylinder Liners Here:

Read More: What Is Cylinder Deactivation Technology and How Does It Work?>>