What is 2 Stroke Compression Ignition Cycle?

The 2 stroke compression ignition cycle (2 stroke diesel) engines are in use mostly in the marine industry. A 2 stroke compression ignition cycle or 2 stroke diesel engine differs from a 4 stroke diesel engine by the way it generates power in the number of revolutions of the crankshaft. Unlike in a 4 stroke diesel engine, the 2 stroke compression ignition cycle produces power in its every revolution. The 2 stroke compression ignition gives way to the traditional four strokes to run its complete cycle. Instead, it merges two strokes into one; thereby making one upward stroke and one downward stroke in every revolution of the crankshaft.

Hence, the 2 stroke cycle engine generates power during each downward stroke of the piston. Thus, it produces double the power output as compared to a 4 stroke cycle engine of the same size. The 2 stroke compression ignition cycle eliminates the suction and exhaust strokes. It uses the only two remaining strokes which are the compression stroke and power stroke. These are known as the upward stroke and downward stroke respectively.

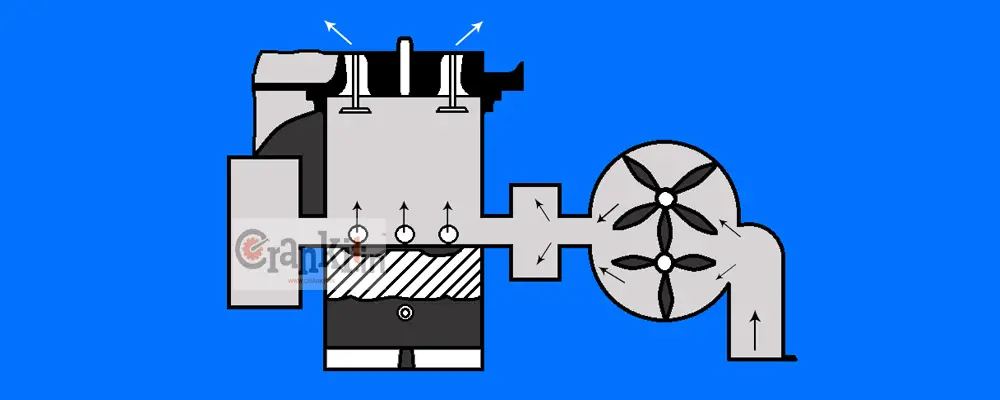

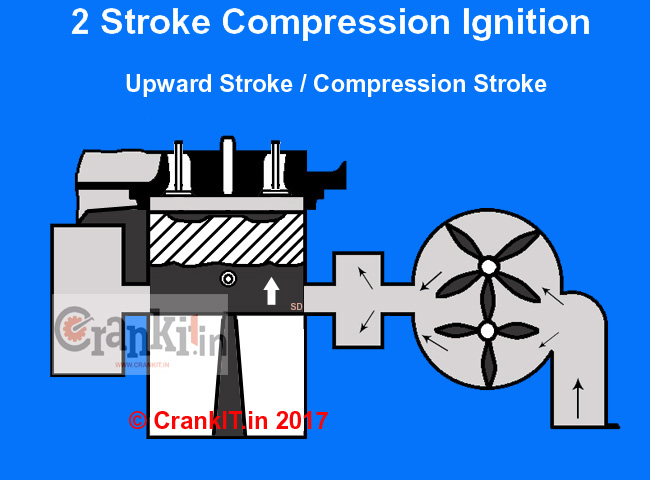

Upward Stroke in 2 Stroke Compression Ignition Cycle:

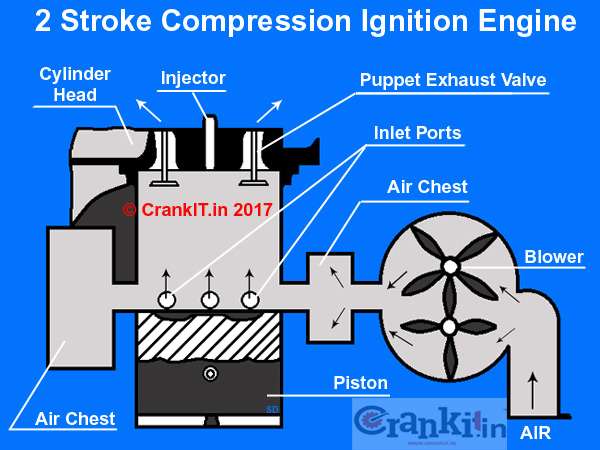

During upward stroke, the piston moves upward i.e. from the bottom dead center to the top dead center. While moving up, it compresses the air in the combustion chamber. A blower pressurizes the fresh air and stores it in an air chest.

When the piston is at the top dead center, it covers/closes the inlet ports or scavenges ports. The compression of air raises its temperature to above 500⁰C. An injector sprays the diesel in the hot air which ignites it in the combustion chamber and produces the power stroke. The power stroke pushes the piston downward and rotates the crankshaft.

Downward Stroke in 2 Stroke Compression Ignition Cycle:

As soon as the ignition takes place, the hot gases expand and push the piston downward rotating the crankshaft. Further downward movement of the piston first opens the exhaust valve. This allows the exhaust gases to escape through the open exhaust port.

During this stroke, the piston first uncovers the inlet / scavenge ports. No sooner the scavenge port opens; it forces the fresh air into the cylinder. The air gathers above the piston crown and rises to the top of the cylinder. It pushes out the remaining exhaust gases from the cylinder in a process known as ‘scavenging’.

Now, the piston is at the bottom dead center of the cylinder is completely filled with fresh air. It starts moving up the cylinder closing off the scavenge ports. Then, the exhaust valve closes completely and compression begins. The injector sprays diesel in the hot air during the upward stroke. This cycle repeats itself and the piston makes two strokes for each revolution of the crankshaft.

What is a 2 Stroke Trunk Piston Engine?

A 2 stroke compression ignition cycle engine is also known as 2 stroke Trunk Piston engine. In this type of engine, the angularity of the connecting rod causes side thrust which it transmits to the cylinder liner thru’ the piston skirt or trunk. Hence, it is also known as a 2 Stroke Trunk Piston Engine. The piston skirt/trunk also acts as a seal and covers the scavenge air-ports when the piston is at TDC. Thus, it prevents the scavenge air from pressurizing the crankcase.

Most manufacturers of the 2 stroke compression ignition engines are Detroit Diesels, Wichmann, Sulzer, Brons and General Motors.

Watch 2 stroke compression ignition cycle in action here:

Read more: How a Four Stroke Diesel Engine Works?>>