What is Diesel Particulate Filter (DPF)?

The NOx & particulate emission from diesel engines is a greater threat to the environment. To reduce its impact, automotive engineers developed DPF to conform to the stricter Euro-6 emission standard. The term DPF stands for Diesel Particulate Filter. It is used in the diesel engine that is Euro-6 emission compliant. The manufacturers use the Diesel Particulate Filter to filter, store and burn the soot particles which are emitted as a result of the combustion process of the diesel.

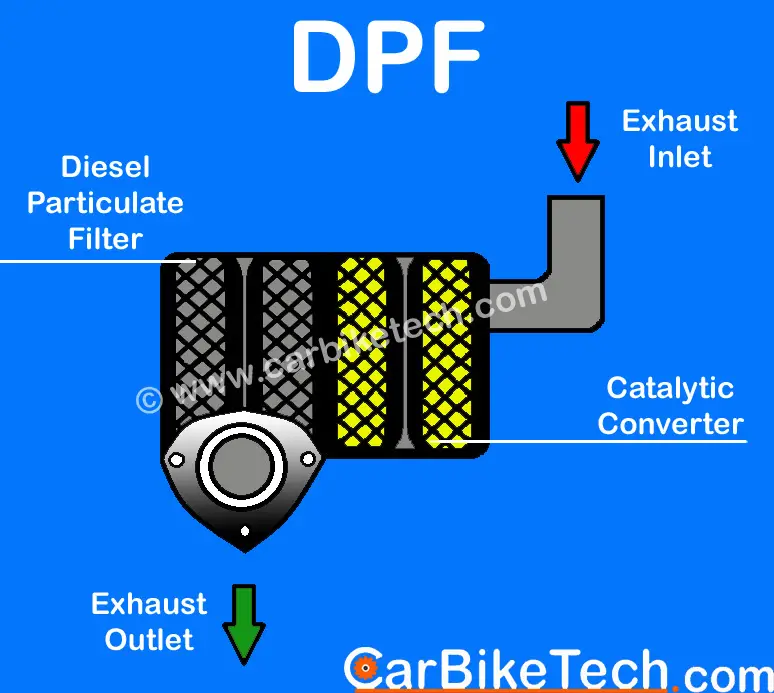

Generally, the oxidation catalytic converter and Diesel Particulate Filter come in a common cylindrical unit. Diesel Particulate Filter consists of silicon carbide. It can filter about 99% of solid particulate matter from the exhaust of a diesel engine. The soot particles or the carbon particles deposited on the filter channels are oxidized into carbon dioxide (CO2) at exhaust temperatures above 600oC. The basic Diesel Particulate Filters are the single-use type. You need to dispose and replace them when they get full after accumulating the ash. More advanced design can also burn off the accumulated soot by using a catalyst.

What are Particulates?

Particulates are the form of carbon that accumulates in the exhaust system of a car’s engine. The particulates originate from various leftovers which depend upon what type they are. In the terms of vehicles, the particulates are the minute solid particles of exhaust gases which an engine emits. The engine emits these particulates mainly in the form of carbon or soot.

You can find this type of carbon particulates mostly in the vehicles that operate on diesel engines. Because of the high compression ratio of the diesel engine, the exhaust coming out from the diesel engines contains the carbon particulates with high density and of bigger size.

Thus, the particulate matter forms a layer of the carbon inside the exhaust system of the engine. This is the main reason why taking care of the exhaust system of the engine is very important. So, it is necessary to limit the quality of carbon particulates emitting to prevent the problems of the environment. Some of the countries have very strict rules about the emission of the engine smoke that can cause the problem to the environment as well as people living in that countries. It is the Environment Protection Agency (EPA) which governs the emission rules in the USA.

How does a Diesel Particulate Filter work?

The unfiltered exhaust flows thru’ the DPF’s channels that are open at the inlet end. The Diesel Particulate Filter core contains porous walls of a ceramic honeycomb structure made of silicon carbide. The exhaust gases then enter into the channels that are open at the outlet end. Furthermore, the exhaust systems take away the exhaust gases. The DPF core retains the soot particles physically. It later burns them off during the regeneration phase. The CDI control unit computes the amount of soot and ash accumulation in the Diesel Particulate Filter with the help of DPF differential pressure sensor.

What is SCR?

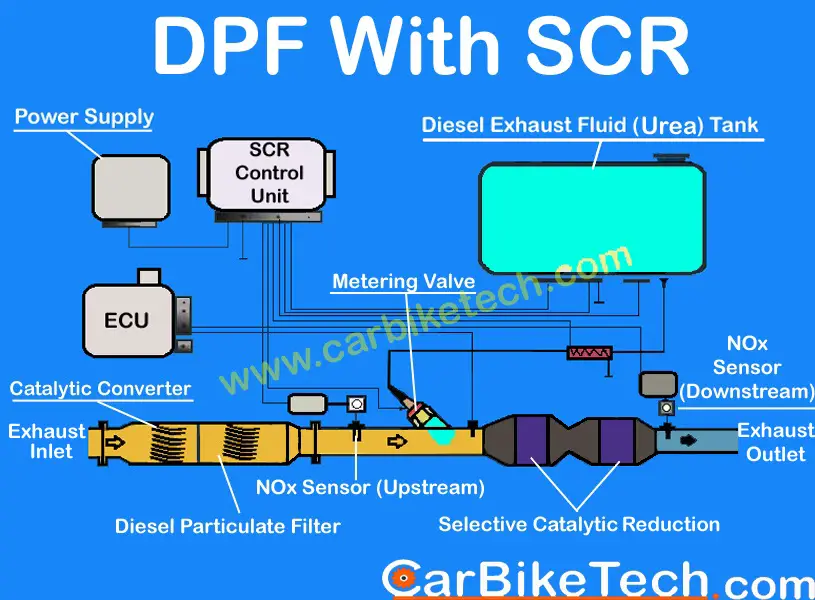

SCR stands for Selective Catalytic Reduction. The engine control module calculates the quantity of reduction agent depending upon the characteristic map. The drive-train sensor then sends this information to the SCR control unit. The control unit then initiates injection of reduction agent thru’ the Diesel Exhaust Fluid metering valve.

Components of Diesel Particulate Filter system:

The temperature sensor upstream of DPF detects the temperature of the exhaust before it enters the DPF. The integral NTC resistor changes its electrical resistance according to the exhaust temperature and then sends a corresponding voltage signal to the CDI control unit. The CDI control unit uses the voltage signal to monitor the rise in exhaust temperature before and during the regeneration phase.

The DPF differential pressure sensor detects the difference between the exhaust upstream and downstream of the DPF. The exhaust pressure sampling pipes upstream and downstream of DPF detect the exhaust pressure difference. Furthermore, the pressure difference between the exhaust pressures upstream and downstream of the DPF acts on the integral piezo-electric pressure sensor element. This produces a voltage which the integrated silicon chip amplifies and passes on to the CDI control unit as a voltage signal.

What is Regeneration?

‘Regeneration’ is the process which burns off the soot particles accumulated in the DPF as CO2. The CDI control unit initiates DPF regeneration by raising the exhaust temperature to above 550oC. The DPF retains the non-combustible ash as a by-product.

The temperature sensor upstream of DPF monitors exhaust temperature during regeneration. The DPF differential pressure sensor detects the difference between the exhaust pressure upstream and downstream of the Diesel Particulate Filter by means of the exhaust pressure sampling pipes upstream and downstream of the DPF.

On the basis of the pressure difference and the exhaust mass, the CDI control unit calculates the amount of soot/ash accumulated in the DPF using a data map. If the accumulated soot exceeds a data-map figure, the CDI control unit initiates regeneration phase. It does so, provided the pre-conditions for regeneration are satisfied. The regeneration time depends upon the temperature. It shortens significantly as exhaust temperature rises.

After regeneration, the CDI control unit measures the pressure difference and compares it with a reference number. From that the CDI control unit computes the ash accumulated in the diesel particulate filter.

Information Source: Daimler-Benz Vans

Read more: How Catalytic Converter works?>>