Advantages of DiASiL Cylinder:

DiASiL stands for Die-cast Aluminium Silicon Cylinder of the engine.

For – Reducing heat-induced power loss in the engine and improved fuel efficiency. By – Yamaha YZF-R15

How Die-cast Aluminium Cylinder Works:

Yamaha recently developed the Die-cast Aluminium Silicon Cylinder technology. The company implemented the all-aluminum cylinder and a forged piston in YZF-R15 bike’s engine.

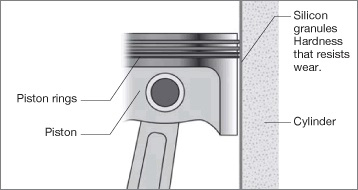

This type of Cylinder is an all-aluminum cylinder. It is made by YAMAHA with its trademarked Aluminium Die-casting technology. Die-cast aluminum alloy contains 20% silicon. It creates a very hard & reliable cylinder surface. Aluminum is a better conductor of heat. It has heat conductivity almost 3 times than that of iron. Since the aluminum is a good conductor of heat and also lighter in weight, DiASiL cylinder effects in better heat dissipation. With the invention of Die-cast Aluminium Cylinders wholly made of aluminum, it will replace the conventional iron sleeve inserts earlier used in engine cylinders in the near future.

According to Yamaha, in YZF-R15 version 2.0, both the piston and cylinder are all-aluminum. Thus, they provide excellent heat dissipation. Its heat dissipation rate is three times better than steel. DiAsil cylinder also eliminates heat-induced engine power loss and helps to improve fuel efficiency. Yamaha claims that the Die-cast Aluminium Silicon cylinder gets a special surface treatment to prevent oil evaporation from the cylinder’s surface and improves oil consumption. The Die-cast Aluminium Silicon cylinder also has excellent hardness quality. It is also considerably resistant to wear & tear as compared to conventional iron sleeves according to Yamaha.

Further information can be obtained here. http://www.yamaha-motor-india.com/16secrets/cylinder/tech.html

Read More: Twin Shocks technology by TVS?>>