What is the Desmodromic Valve Mechanism?

The word Desmodromic originates from two Greek words, Desmos meaning “bond” or “knot” and Dromos meaning “track” or “way.” Thus, it represents the significant features of the engine valves being continuously “bound” to the camshaft. A desmodromic valve is nothing but a reciprocating engine poppet valve. A cam and leverage system positively closes it instead of a conventional spring mechanism. In a typical four-stroke engine, the valves open/close. They suck the air/fuel mixture into the cylinder at the start of the intake stroke. And then drive out the exhaust gases at the end of the stroke.

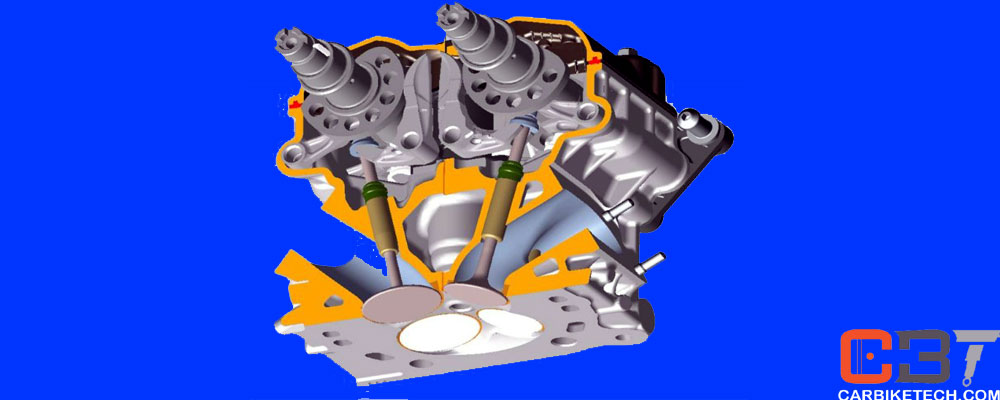

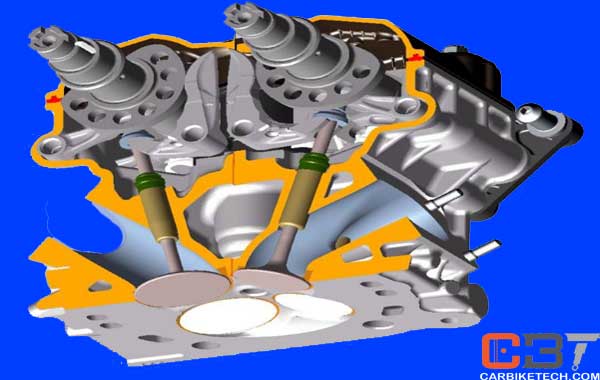

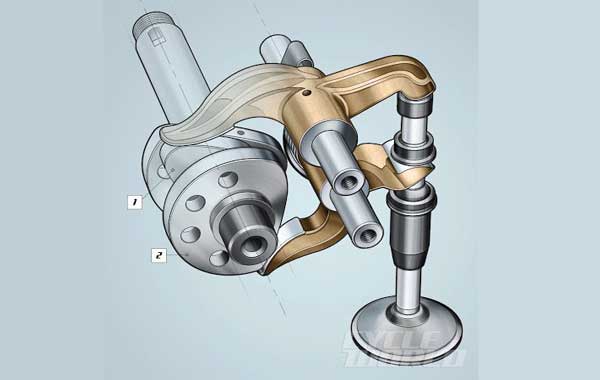

A cam opens the valves in a conventional four-stroke engine, and a return spring closes them. An engine with desmodromic valves has two cams and two actuators, each for positive opening and closing. However, engineers designed them without the return spring. The universal notion is that Ducati chose Desmodromic Valve systems for more engine revolutions. It also picked aggressive ramp rates when valve springs were undoubtedly the restrictive factor for both.

Other manufacturers were similarly disappointed. Finally, however, they at least tried out with the research of the Desmodromic valve. Since then, metallurgy and manufacturing changes have permitted most manufacturers to meet traditional springs’ valvetrain goals.

Development:

A few years back, Ducati could still display fuel consumption advantages in their system. That was enough to keep using the Desmodromic Valve mechanism for some more time. As a result, the valve service intervals slowly extended for Ducati’s engines. However, they are still shorter than typical for similar bikes from other manufacturers. Arguably the design features that defined Ducati bikes for decades were V-twin engines and desmodromic valve actuation.

The standard valve spring mechanism is suitable for conventional, mass-produced engines. These engines do not rotate at high speeds and need low maintenance. However, at the period of initial Desmodromic valve development stages, valve springs were a significant cause for limitation on engine performance. It was because they would break from metal fatigue.

Improvements:

In the 1950s, manufacturers introduced a new vacuum melt process. It helped to remove impurities from the metal in valve springs. Thus, it increased their life and efficiency significantly. However, many springs would still fail at constant operation above 8000 RPM. Hence, the engineers designed the Desmodromic valve system to solve this problem by completely removing the need for a spring.

Furthermore, as the engine increases its maximum R.P.M., you need a higher spring force to stop valve float. Hence, it leads to larger springs (with increased spring-mass, and thus, greater inertia) & cam drag. Besides, it creates higher wear on the parts at all speeds. Therefore, engineers addressed these problems by using the Desmodromic valve mechanism.

Design of Desmodromic Valve Mechanism:

The engineers conceived the fully controlled valve movement during the early stages of engine development. However, developing a system that functioned consistently and was not overly complex took long. One Gustav Mees first mentioned these systems in his patents in 1896.

One of the earliest designs included Austin’s marine engine of 1910 that produced 300 bhp in a speedboat called “Irene I.” It had an all-aluminum, twin-overhead-valve engine with twin magnetos, two carburetors, and Desmodromic valves. The 1914 Grand Prix Delage and Nagant also used this system. However, it was quite unlike the present-day Ducati system.

Watch Desmodromic Valve Engine in Action Here:

Azzariti, an Italian manufacturer from 1933 to 1934, produced 173cc and 348cc twin-cylinder engines. Some of them had a Desmodromic valve mechanism, whereby a separate camshaft would close the valve. Besides, the Mercedes-Benz W196 Formula One racing car and the Mercedes-Benz 300SLR sports racing car of 1955 had this mechanism.

Fabio Taglioni, a Ducati engineer, developed this system for the Ducati 125 Grand Prix. Thus, he created the Ducati 125 Desmo. The engineers that came after him continued the development of this mechanism. As a result, Ducati holds several patents relating to this technology. Besides, the engineers applied it to top-of-the-range production Ducati motorcycles since 1968. And, they introduced the “widecase” Mark 3 single-cylinder engines. Finally, in 1959, the Maserati brothers announced a Desmodromic valve four-cylinder, 2000cc engine for their last O.S.C.A. Barchetta.

Advantages of Desmodromic Valve:

- Desmodromic valve opens and closes the valves mechanically. No spring required.

- In theory, you can then spin the engine as fast as you can up to what the pistons would support.

- Prevention of valve float at high engine speeds.

- A conventional solution for valve float is to stiffen the springs. It increases the static seat pressure of the valve that holds the valve in a closed position. It is helpful at higher engine speeds because of a reduction in the valve float.

- The higher spring pressure causes greater friction in the valvetrain. However, the Desmodromic valve system avoids this problem. It is because it does not have to overcome the force of the spring.

- This system must deal with the inertia of the two rocker arms per valve. So, this advantage is subject to the designer’s skill.

- Besides, these systems generally need to deal with sliding friction between the cam and rocker arm. And, therefore may have greater wear. Hence, the engineers hard-chromed the contact points on most Ducati rocker arms to reduce this wear.

Disadvantages of Desmodromic Valve:

- Having no springs in the system makes it had to take up tolerances and expansion differences. As a result, the valves are loose when the engine is cold, which leads to heat getting to places it shouldn’t. Thus, it leads to a large increase in wear.

- The engine becomes noisy.

- Since you can’t entirely close up all the slack in the system, the followers have a tough time maintaining a bearing oil film. They tend to get slapped into the cam, which leads to a very localised wear.

- Having a variable cam profile is very difficult with Desmodromic valve also. You can adjust the valve timing, but that is all.

- Desmo systems are both expensive to build and very labor intensive to maintain.

- Metal fatigue is a real problem.

- It complicates the mechanics considerably.