What is CCE?

The term CCE stands for Controlled Combustion Engine. To identify a type of experimental internal combustion engine (ICE) designed by Brad Howell-Smith, they used the term Controlled Combustion Engine. It is a term used by TechViki, an engine designing company. The engine uses two counter-rotating cams in this design instead of a crankshaft. It also has cylinders that oppose each other in a boxer flat engine or an X engine arrangement.

In 1995, the idea came to Howell-Smith, an automotive engineer from Australia. He designed five different engine layouts with variations on each and started Revolution Engine Technologies Pty Ltd in 1996. He also set up a research and development site. The prototype was displayed at the 1996 Sydney International Motor Show. After that, an interest shown by the Middle East automotive market shifted focus towards its automotive applications.

Controlled Combustion Engine: Design

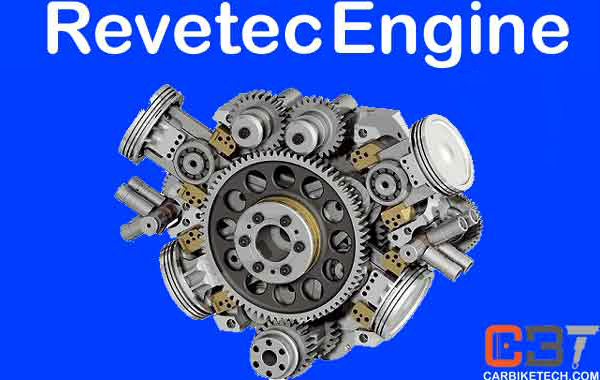

The Revetec engine design consisted of two counter-rotating “trilobate” (three-lobed) cams geared together. Thus, both cams contribute to the forward motion, alongwith the profile of both cams, two bearings (four bearings in all) run. They stay in contact with the cams at all times. The bearings mount on the underside of the two inter-connected pistons, which maintain the required clearance throughout the stroke.

The two cams rotate and raise the piston in a scissor-like action to the bearings. Once they reach the top of the stroke, the air-fuel mixture fires. This is the power stroke during which it reaches the maximum mechanical advantage after the piston has moved approximately 5% of its travel from the top dead center (approx. 10° After TDC). Thus, it better uses the high cylinder pressures in the cycle. This is quite different from a conventional engine that reaches its maximum mechanical advantage after the piston has moved approximately 40% of its travel from TDC (approx. 60° After TDC). As a result, a CCE can idle at a much lower engine RPM.

Increased Power:

Because the piston assembly only moves in one dimension (unlike in an engine with connecting rods), contact with the cylinder wall is minimum. Thus, it reduces wear & tear and lubrication requirements. In addition, the cams create less piston shock, which allows the use of ceramic components. Besides, the Controlled Combustion Engine engine can spin in either direction if symmetrical lobes are used. The length from the point of bearing contact to the center of the output shaft (not the stroke) determines the effective cranking distance.

The dual bearings contact the two cams on the opposite side that cancels the side forces out. As a result, the piston assembly does not experience any side force, reducing wear and tear and the need for lubrication at the cylinder contact point. One unit, consisting of five moving components, produces six power strokes per revolution. Thus, increasing the number of lobes on each cam to five produces ten power strokes without increasing the number of components.

Controlled Combustion Engine: Claimed Advantages

The predicted production power to dressed-weight ratio is 0.40 bhp/lb, based on 2007 testing of the X4v2 engine. For comparison a Continental 100 hp (75 kW) engine is 0.465 hp/lb. dressed.

Good efficiency, for a gasoline engine, when running lean.

Few moving and total components. As a result of fewer components, and easier to manufacture than conventional engines.

Identical cylinder head assembly (“top end”) to conventional engines. Could adapt or use most existing cylinder head technologies.

Flexibility in design – Could be a four-stroke, two-stroke, petrol, diesel or gas, natural aspiration, or forced-fed engine.

Elimination of irregularly reciprocating components such as connecting rods. No need for second-order balancing a Controlled Combustion Engine.

Output shaft could run in either direction if manufacturers employ multi-lobed cams with symmetrical lobes.

The manufacturers could design the Controlled Combustion Engine to operate at greatly reduced operational speeds, with high torque output delivery.

Significant reduction in stroke reduces heat losses through cylinder walls.

Prolonged piston-dwell is possible because engine design allows a lower-than-normal compression ratio. Thus, reducing power loss from compression stroke.

Some More:

Ability to fire on a leaner mixture than conventional engines.

Manufacturers could apply maximum mechanical advantage to output shaft at only 20 degrees ATDC using high cylinder pressure early in the stroke. This is in contrast to around 60-70 degrees ATDC for conventional engines.

Manufacturers could achieve lower emissions in a Controlled Combustion Engine due to increased control over combustion.

Manufacturers could achieve low idle speed at the top of the stroke due to increased mechanical efficiency.

Little or no cylinder bore contact/piston side thrust. Hence, reduced wear on the cylinder bore.

It could have different port timing on compression stroke than power stroke. Thus, allowing better control.

Lower center of gravity on the boxer type Controlled Combustion Engine design.

Due to controlled piston acceleration rates, the Controlled Combustion Engine decreases engine vibrations.

Manufacturers could use a hollow output shaft for specialty applications, such as peristaltic pumps.

Low emissions

Reliability: especially when running lean as necessary for good fuel economy.

The Revetec engine shows a flat torque curve.

Test Results:

According to April 2008 first Independently Certified Test Report, Revetec achieved a repeatable figure of 212g/kWh with 38.6% efficiency. In addition, the X4v2 has a huge amount of torque over a much larger range of rpm than a conventional internal combustion engine.

Accordingly, you could see a 30% reduction in fuel consumption and a 30% reduction in emissions if you used the full acceleration power of the X4v2 all the time. This would also provide a 20% increase in pick-up abilities.