What is Bore-Stroke Ratio?

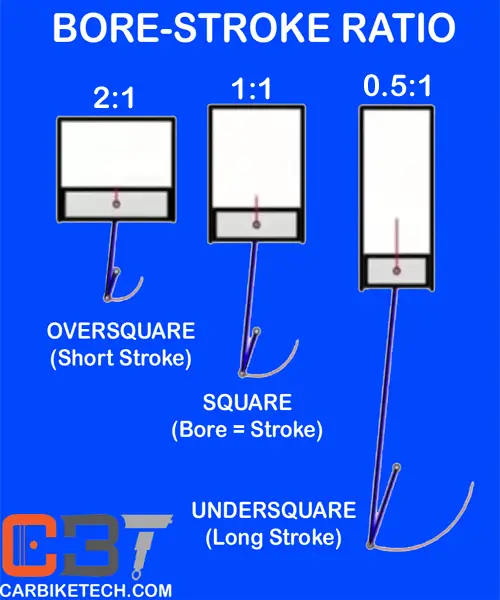

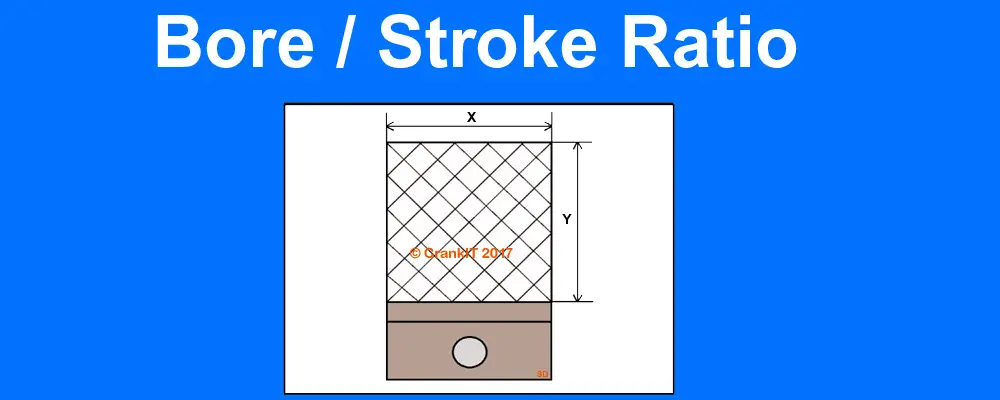

Bore-Stroke Ratio is the ratio between the dimensions of the engine cylinder bore diameter to its piston stroke-length. The cylinder bore diameter divided by the stroke-length gives the Bore-to-Stroke ratio. The ‘Bore-stroke ratio’ is an important factor which determines engine’s power & torque characteristics.

Bore-Stroke ratio = Cylinder Bore diameter / Piston Stroke-Length

The engineers also classify and categorize the automotive engines according to their shapes. It’s the shape of cylinders as seen from the side of the engine.

Principally, there are three types of geometrical shapes around which the engineers design conventional engines with. They are –

- Square Engine

- Under Square Engine

- Over Square Engine

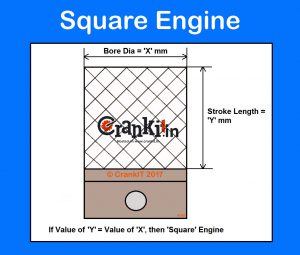

What is a ‘Square Engine’ and how Bore-Stroke Ratio affects its design?

An engine is called a ‘Square Engine’ when its cylinder bore diameter & stroke-length are almost equal which forms a geometrical figure of a perfect ‘square’. The bore-stroke ratio is almost 1:1 in Square engine design.

For e.g. an engine with a bore diameter of 83mm and stroke-length of 83mm which forms a perfect square. It provides a perfect balance between speed and pulling ability.

Therefore, the ‘Bore -stroke ratio’ = 1:1

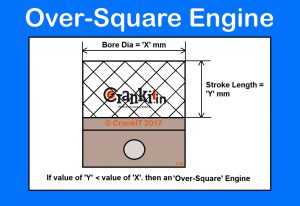

What is an ‘Over Square’ Engine and how Bore-Stroke Ratio affects its design?

An engine is called an ‘Over-square’ engine when its cylinder bore is wider than its stroke. In this design, the stroke-length is shorter than the cylinder bore. Manufacturers also refer it as a ‘short-stroke’ engine. Generally, ‘Over-square’ design tends to produce higher engine speeds. Therefore, engineers refer to it as a ‘high-speed’ engine. As the stroke-length is short, the piston has to travel a shorter distance. Hence, this design tends to produce higher engine speed and is typically used in high-speed cars & bikes.

‘Over-Square’ engine has the bore-stroke ratio greater than 1:1.

For e.g. an engine with the bore diameter of 83mm and stroke-length of 67mm which forms an ‘over square design’.

Therefore, the ‘Bore -stroke ratio’ = 1.23 : 1

Advantages of ‘Over-Square’ Design:

- Less frictional losses & load on bearings.

- Higher engine speeds.

- Reduces engine height thereby lowering the bonnet line.

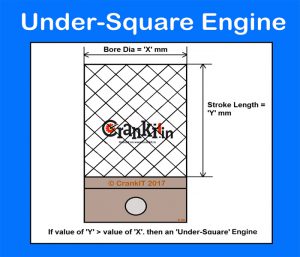

What is an ‘Under Square’ Engine and how Bore-Stroke Ratio affects it?

An engine is called an ‘Under-square’ engine when it has a longer stroke. In this engine, the stroke-length is longer than the cylinder bore. Generally, ‘Under-Square’ design tends to produce comparatively higher torque. Hence, engineers also refer to it as ‘high-torque’ engine. As the stroke-length is long, the piston has to travel a longer distance which tends to increase engine’s torque. Hence, the manufacturer typically uses it in commercial vehicles such as trucks, buses and earth-moving equipment.

‘Under-Square’ engine has the bore-stroke ratio lesser than 1:1.

For e.g. an engine with a bore diameter of 70mm and stroke-length of 83mm which forms an ‘under square design’.

Therefore, the ‘Bore-stroke ratio’ = 0.84 : 1

Advantages of ‘Under-Square’ Design:

- Higher engine torque.

- Can pull heavier loads.

The engine manufacturers try to attain the near-perfect ratio from these designs depending upon the application for which they intend to develop the engine.